- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

HP300

ONA

847490

1

High Manganese

30 days

6 Months

TT, Paypal, Credit Card, Western Union

Iron Pallet

| Availability: | |

|---|---|

| Quantity: | |

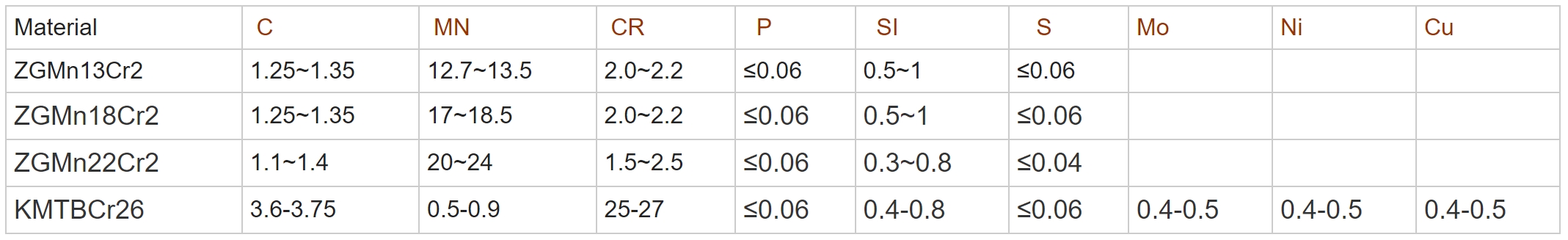

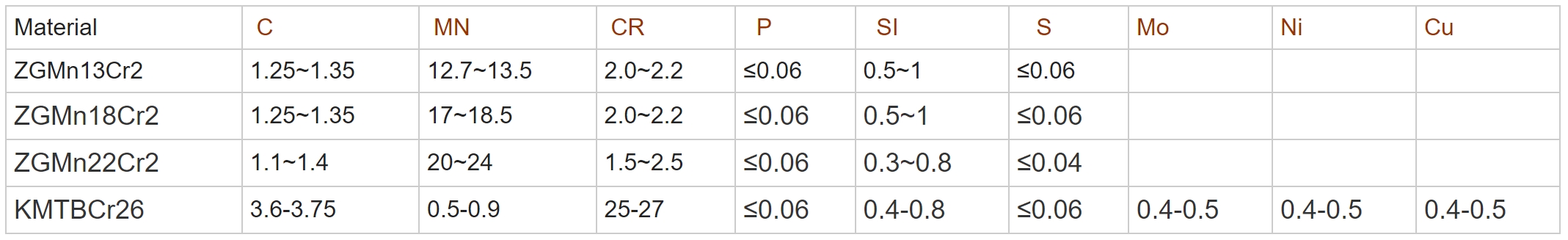

The cone crusher concave is made of high manganese steel, which is durable and wear-resistant. You can insert alloy or ceramics to increase the using life. The surface is painted for better protection. It is manufactured using a casting process to ensure a smooth surface, precise size, and uniform weight distribution.

It has high hardness and wear resistance to ensure a long service life. This product is sold directly from the factory and has a high cost-effectiveness. Heat treatment processes such as annealing, quenching, and tempering further improv its durability. We can provide heat treatment report:

The cone crusher bowl liner suit to HP300 Metso can be customized according to the part number or customer requirements. It is packaged using steel pallet packaging to ensure safe and efficient transportation.

| Parameter | Value |

|---|---|

| Material | High manganese steel (customizable composition) |

| Surface Treatment | Spray painting |

| Manufacturing Process | Casting |

| Advantages | Smooth surface, precise dimensions, uniform weight distribution |

| Hardness | High hardness, wear-resistant, long service life |

| Sales Model | Direct factory sale, cost-effective |

| Heat Treatment | Annealing, quenching, tempering |

| Specifications | Customizable based on part number or customer request |

| Packaging | Steel pallet packaging |

Material: Made of high manganese steel with customizable composition options.

Surface Treatment: Paint coating for enhanced protection and durability.

Manufacturing Process: Casting to ensure solid structural integrity and precise dimensions.

Smooth surface, precise size, uniform weight distribution.

High hardness, wear resistance, longer service life.

Direct sales from the manufacturer, providing cost-effective solutions.

Mining: used for crushing minerals and ores.

Metallurgy: used for various processing and refining applications.

Construction: used for projects requiring aggregates.

Road construction: used for the production of road base materials.

Chemicals: used for the production of chemical materials.

Silicates: used for processing silicate materials.

1. What is the surface treatment of the Cone Crusher Spare Parts bowl liner?

The surface of the bowl liner is painted to enhance protection and durability.

2. What are the advantages of using a cone crusher spare part bowl liner?

The product has a smooth surface, precise dimensions, uniform weight distribution, high hardness and excellent wear resistance. It ensures a longer service life.

3. Is the bowl liner compatible with the original equipment?

Yes, our bowl liners are designed to be fully compatible with the original cone crusher, ensuring seamless performance.

4. Can the bowl liner be customized?

Yes, the bowl liner can be customized in terms of color, material and other specifications according to your specific needs.

5. What industries are your bowl liners used for?

Our bowl liners are commonly used in mining, metallurgy, construction, road construction, chemicals and silicate industries.

The cone crusher concave is made of high manganese steel, which is durable and wear-resistant. You can insert alloy or ceramics to increase the using life. The surface is painted for better protection. It is manufactured using a casting process to ensure a smooth surface, precise size, and uniform weight distribution.

It has high hardness and wear resistance to ensure a long service life. This product is sold directly from the factory and has a high cost-effectiveness. Heat treatment processes such as annealing, quenching, and tempering further improv its durability. We can provide heat treatment report:

The cone crusher bowl liner suit to HP300 Metso can be customized according to the part number or customer requirements. It is packaged using steel pallet packaging to ensure safe and efficient transportation.

| Parameter | Value |

|---|---|

| Material | High manganese steel (customizable composition) |

| Surface Treatment | Spray painting |

| Manufacturing Process | Casting |

| Advantages | Smooth surface, precise dimensions, uniform weight distribution |

| Hardness | High hardness, wear-resistant, long service life |

| Sales Model | Direct factory sale, cost-effective |

| Heat Treatment | Annealing, quenching, tempering |

| Specifications | Customizable based on part number or customer request |

| Packaging | Steel pallet packaging |

Material: Made of high manganese steel with customizable composition options.

Surface Treatment: Paint coating for enhanced protection and durability.

Manufacturing Process: Casting to ensure solid structural integrity and precise dimensions.

Smooth surface, precise size, uniform weight distribution.

High hardness, wear resistance, longer service life.

Direct sales from the manufacturer, providing cost-effective solutions.

Mining: used for crushing minerals and ores.

Metallurgy: used for various processing and refining applications.

Construction: used for projects requiring aggregates.

Road construction: used for the production of road base materials.

Chemicals: used for the production of chemical materials.

Silicates: used for processing silicate materials.

1. What is the surface treatment of the Cone Crusher Spare Parts bowl liner?

The surface of the bowl liner is painted to enhance protection and durability.

2. What are the advantages of using a cone crusher spare part bowl liner?

The product has a smooth surface, precise dimensions, uniform weight distribution, high hardness and excellent wear resistance. It ensures a longer service life.

3. Is the bowl liner compatible with the original equipment?

Yes, our bowl liners are designed to be fully compatible with the original cone crusher, ensuring seamless performance.

4. Can the bowl liner be customized?

Yes, the bowl liner can be customized in terms of color, material and other specifications according to your specific needs.

5. What industries are your bowl liners used for?

Our bowl liners are commonly used in mining, metallurgy, construction, road construction, chemicals and silicate industries.