- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-06-30 Origin: Site

Impact crusher parts are the rotor, blow bars or hammers, breaker plates, and wear plates. The rotor spins and gives energy to the material. This makes the material smaller inside the machine. Blow bars or hammers hit the material that goes in. Breaker plates help control the size and shape of the product. Wear plates keep the machine’s housing safe from wearing out. Knowing what each part does helps workers keep the crusher working well. It also helps stop the machine from breaking down. The table below shows how these parts help the crusher work better:

Impact Crusher Part | Function and Benefit |

|---|---|

Rotor | Moves material fast for more work and fewer stops. |

Blow Bars | Hit and break down material quickly and well. |

Breaker Plates | Shape the product and take hits, so they last longer. |

Wear Plates | Protect inside parts, so the machine lasts longer. |

ONA gives strong impact crusher parts, jaw crusher parts, and cone crusher parts to many places. Their team uses new materials and careful work to make sure every crusher works well. People trust ONA because they know how impact crushers work. They also help with all big types of impact crushers.

Impact crushers have four main parts. These are the rotor, blow bars, breaker plates, and wear plates. Each part has a special job to help break rocks well.The rotor spins very fast to give energy. Blow bars hit rocks and break them. Breaker plates help shape the crushed rocks. Wear plates protect the machine from getting damaged.You should check parts like blow bars and wear plates often. Replace them on time to keep the crusher working well. This helps stop big and expensive problems.Using good parts from trusted suppliers like ONA is important. It makes the machine last longer. It also helps the crusher work better and makes fixing it easier.Taking care of the crusher and using strong parts is smart. It helps the crusher last longer and need fewer repairs. This can save up to 30% on running costs.

Impact crushers are strong machines. People use them in mining, quarrying, and recycling. These machines break down big rocks into smaller pieces. They do this by hitting the rocks very fast. The main parts are the rotor, blow bars, breaker plates, and wear plates. Each part has a special job in the machine. These parts help the crusher work well and last longer. Knowing about these parts helps workers pick the right crusher. There are different types like primary, secondary, and tertiary impact crushers.

The rotor is the most important part of the impact crusher. It holds the blow bars or hammers. The rotor spins very fast. When it spins, it gives energy to the rocks. This makes the rocks break apart. The shape and weight of the rotor matter a lot. Where the blow bars are placed also matters. These things change how well the crusher works.

If the rotor is made well, it can spin slower but still work hard. This saves energy and makes the machine last longer.

ONA makes rotors from strong metals. These rotors can crush hard rocks like granite. ONA’s rotors fit many brands and meet high standards. They work in both horizontal and vertical shaft impact crushers.

Process Condition | Effect on Production Capacity and Product Quality |

|---|---|

High rotor rotation speed | Makes more product and better shapes. |

Low rotor rotation speed | Makes less product and worse shapes. |

Rotors can break if they get too much stress or if rocks go in unevenly. ONA uses good machines and checks to stop these problems. This helps each rotor work well in all types of impact crushers.

Blow bars are the parts that hit the rocks. They are attached to the rotor. When the rotor spins, the blow bars strike the rocks. The kind of metal used for blow bars is important. It changes how long they last and how strong they are.

ONA makes blow bars from special metals. Some are tungsten carbide, martensitic steel, high-chrome steel, or ceramic composites. Each metal is good for different jobs. Some are best for big rocks, others for mixed or hard rocks.

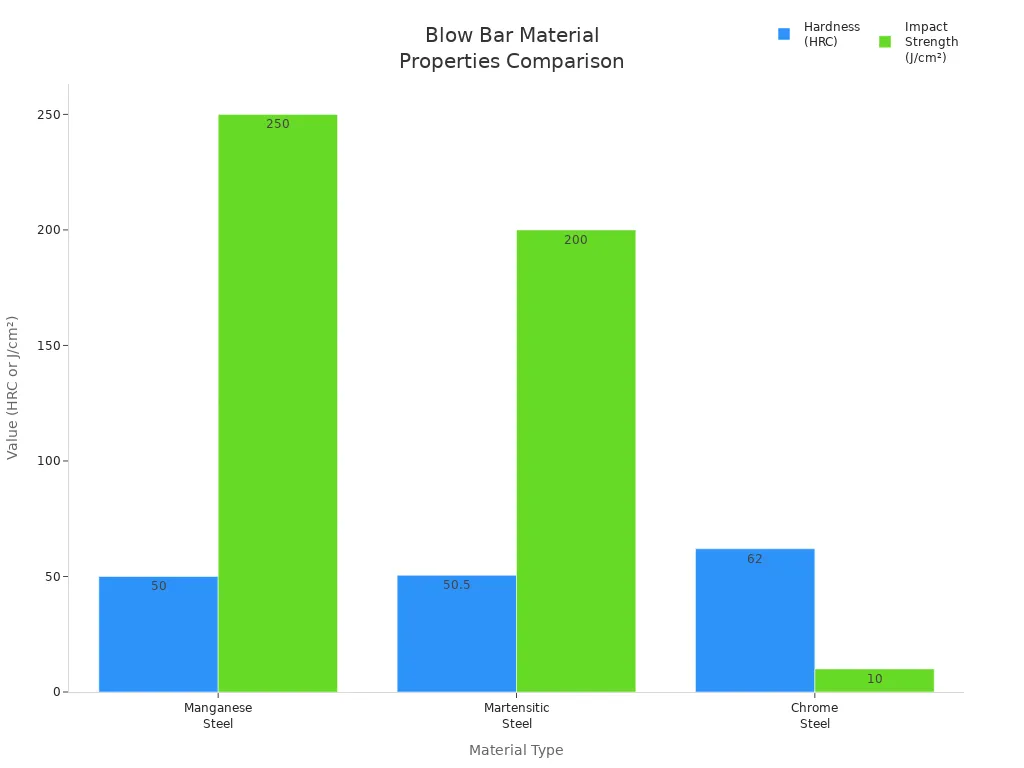

Material Type | Hardness (HRC) | Impact Strength (J/cm²) | Key Characteristics and Usage |

|---|---|---|---|

Manganese Steel | ~20-50 | ~250 | Gets harder with use, very tough, good for big soft rocks like limestone. |

Martensitic Steel | 44-57 | 100-300 | Hard and tough, good for recycling and mixed rocks. |

Chrome Steel | 60-64 | ~10 | Very hard, wears slowly, not as tough, best for crushing natural stones. |

Ceramic Composite | N/A | N/A | Mixes metal and ceramic, lasts 3-5 times longer than martensitic steel. |

Some blow bars can crush up to 400,000 tons before they need changing. This depends on the rocks and how well the machine is cared for. ONA’s blow bars fit many brands. They are easy to flip and replace. This saves time and money.

Breaker plates line the inside of the crusher. After the blow bars hit the rocks, the rocks bounce off the breaker plates. This helps break the rocks into even smaller pieces. The breaker plates help make the rocks the right size and shape.

Breaker plates are made from strong metals like high manganese steel. Some have special coatings like TiC or SiC. These coatings help the plates last longer. ONA uses special treatments to make the plates even stronger.

Breaker plates are very important in secondary and tertiary impact crushers. They help control the size and shape of the rocks.

ONA makes sure each breaker plate fits just right. Their plates work well even in tough jobs. They help the crusher run smoothly.

Wear plates protect the inside of the crusher. They stop the machine from getting scratched or broken. Wear plates take the hits so the rest of the machine stays safe.

ONA uses strong metals for wear plates. Some are made from alloyed steel or self-lubricating materials. These plates last longer and protect against rust. ONA’s wear plates need less fixing and help the crusher run better. This is very important for big crushers.

Wear plates help the crusher work well and last longer.

If wear plates are in bad shape, the machine may break or work poorly.

It is important to check and change wear plates often.

ONA checks every part to make sure it is good. Their wear plates fit many brands and work in all kinds of impact crushers.

Tip: Check wear plates often and change them before they get too thin. This helps stop big problems and keeps your crusher working.

Taking care of an impact crusher helps it work safely. Good maintenance also makes the machine last longer. Regular checks stop surprise problems. ONA says to have a plan for checking, changing, and picking the right spare parts.

Checking the machine every day is very important. Workers look at the rotor, blow bars, wear liners, belts, and bearings. They check for things like loose parts, cracks, or damage. They use tools to measure how thick the liners and blow bars are. Fasteners on blow bars and liners must stay tight. Workers also watch the flywheel speed, hydraulic pressure, and electric readings. These checks help find problems early.

Tip: Write down what you find in a logbook. This helps you know when to fix or change parts.

Recommended Inspection Steps:

Look at all main impact crusher parts every day.

Put grease on bearings as the maker says.

Check fasteners and tighten if needed.

Watch for changes in how the machine works.

Make sure the rotor is balanced and in the right spot.

Move curtains to help stop wear.

Turn or change blow bars if they have chips or cracks.

Change liners before they get too thin.

Look for leaks in the hydraulic system.

Follow the service plan for bigger fixes.

Changing old parts at the right time keeps the crusher working well. Workers look for cracks, chips, rough spots, or parts that are too small. Blow bars, breaker plate liners, and frame liners often need to be changed. Measuring wear and keeping notes helps plan for new parts before they break.

Signs that parts need to be changed:

You see cracks or chips

The surface feels rough

The part is too thin

The wear is not even

ONA’s team helps customers with advice on changing parts. They help pick the right parts for each crusher. Their help makes sure parts are put in safely and the right way.

Picking real spare parts helps the crusher last longer. ONA makes spare parts with strong metal and new casting methods. Every part meets high quality rules like CE and ISO. ONA checks each part for hardness, strength, and fit.

Benefit of ONA Spare Parts | Description |

|---|---|

Long Service Life | Made to last long and need less fixing |

Perfect Fit | OEM support makes them easy to put in |

High Performance | Strong against wear and good for hard jobs |

Full Inventory | Fast delivery for impact crusher, jaw crusher parts, and cone crusher parts |

ONA keeps many parts ready to send out fast. Their team helps with putting in parts and gives tips for care. This service helps customers keep their crusher working well.

Note: Using real ONA spare parts keeps your machine safe and working its best in mining and quarrying.

ONA is known for making good impact crusher parts. They make all their parts in their own factory. Each part is made from the original plans. This makes sure the parts fit right and work well. ONA uses strong materials and new machines to build each part. They check every part with special tools like 3D detectors and hardness testers. ONA follows many world rules, such as:

ISO 9001 quality management system

ISO 14001 environmental management

ISO 45001 occupational health and safety

TS (Technical Specification) standards

CE certification

These rules show ONA wants to make safe and top-quality parts. ONA also makes jaw crusher and cone crusher parts using these same rules.

ONA gives great help to people who use impact crushers. They offer help all day and night for setup and use. Their team has skilled engineers who help during setup. ONA sends spare parts fast to keep crushers working. They give a warranty that lasts as long as the original part. ONA can also make special parts if customers need them. Their team has over 10 years of mining and building experience. Customers get help picking, setting up, and fixing parts.

ONA’s team helps customers fix problems quickly. This means less waiting and better crusher work.

ONA sends impact crusher parts to over 50 countries. They have service centers in many places like Asia, North America, South America, Australia, Central America, the Middle East, and Africa. These centers keep parts close to customers for quick delivery. ONA has workshops and programs to swap old parts fast. Local teams help with fixing and setting up parts. ONA’s worldwide network means customers always get good parts and help.

Aspect | Details |

|---|---|

Export Reach | Products supplied to more than 50 countries |

Annual Turnover | About 5 million US dollars |

Engineering Team | More than 10 engineers |

Product Range | Jaw crusher parts, cone crusher parts, impact crusher parts, VSI crusher parts, liners |

OEM Standards | Parts made from original plans for best fit |

Quality Assurance Equipment | 3D detectors, hardness testers, flaw detectors, roughness meters |

After-sales Service | 5 engineers with over 10 years of experience give support |

Supported Major Impact Crusher Brands | ONA supports many types of impact crushers |

ONA’s worldwide supply and expert team make it a trusted choice for impact crusher needs.

Knowing about the main impact crusher parts and what they do helps workers keep the machines working well. Good parts like strong blow bars and liners make the machines last longer. They also help stop the machines from breaking down often. Doing regular checks, cleaning, and writing down what you do helps stop big problems. This also makes the crusher last more years.

Good parts and care give these benefits:

Machines stop less and cost less to fix

Crushers work longer and do more work

You can save up to 30% on running costs

ONA is a trusted company for impact crusher, jaw crusher, and cone crusher parts. Their team gives fast help and support. This helps people use their crushers safely and well all over the world.

You might see the crusher not working as well. The rocks may come out in different sizes. You may also see worn spots on blow bars or wear plates. Checking the machine often helps find cracks or thin spots. ONA says to change parts before they break. This keeps the crusher working well.

ONA uses new machines and careful checks. Every part is made from the real design plans. The team checks how hard, strong, and well each part fits. They use 3D tools and special testers to look for problems. This makes sure every part is very good.

ONA makes parts that work with many crusher brands. Their engineers use exact sizes and real plans. People can get parts for jaw crushers, cone crushers, and impact crushers. ONA’s team helps you pick the right part.

Doing regular checks stops surprise problems and helps the crusher last longer. Changing blow bars and wear plates keeps the crusher working well. ONA gives help and has many spare parts ready for quick service.

People can go to ONA’s official website to see all the parts. The site shows jaw crusher and cone crusher parts too. You can find more info and get help to order fast.