- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-07-07 Origin: Site

A concrete crusher helps break old concrete into small pieces. You put construction waste into the crusher. The crusher uses strong force to crush it. This helps recycle concrete. Recycling concrete means less trash goes to landfills. It also saves important resources. In the United States, concrete is about 85% of construction waste. This shows concrete is a big part of demolition and recycling. More companies now recycle concrete every year. The global concrete recycling market keeps growing. Using a concrete crusher turns waste into useful material. This makes your project better and helps the environment. Many industries use jaw crusher parts and high manganese liner. These parts help the crusher work better during recycling.

Region | Annual Construction and Demolition Waste (CDW) Output (2016) |

|---|---|

United States | 534 million tons |

European Union | 924 million tons |

Concrete crushers smash old concrete into tiny pieces. This helps recycle and cuts down on waste.There are many kinds of crushers. These include jaw, cone, impact, and mobile crushers. Each one works best for certain jobs and materials.Using crushers saves money. It lowers landfill costs and means you need fewer new materials.Crushing concrete is good for the environment. It cuts pollution, saves resources, and lowers carbon emissions.Following safety rules is important. Doing regular maintenance keeps crushers working well and your worksite safe.

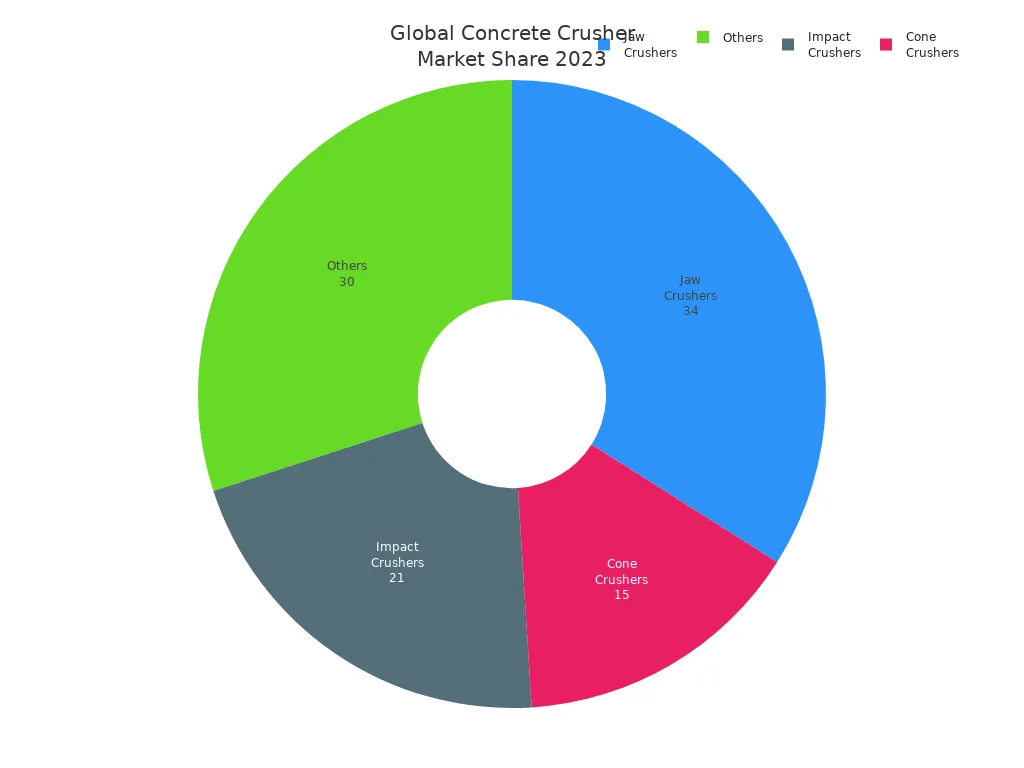

You should know the main types of concrete crushers. Each type is good for certain jobs. ONA sells jaw crusher parts, cone crusher parts, and impact crusher parts. They also have high manganese liners and spare parts. ONA is an OEM manufacturer. They use strict quality checks and new technology. Their products are trusted around the world. Chief Engineer Jhon Wu leads the technical team. They help you pick the right crusher and give support after you buy.

Jaw crushers are very important for recycling concrete. You put big pieces of concrete into the machine. The crusher has two jaws. One jaw stays still and the other moves. The jaws crush the concrete. This works well for strong concrete and asphalt. Jaw crushers make clean pieces you can use again. You can use small crushers for bricks and blocks. Use bigger crushers for large jobs. ONA’s jaw crusher parts and high manganese liners last a long time.

Cone crushers have a spinning cone inside a steel bowl. They crush concrete into smaller pieces. You get even, high-quality aggregate. Cone crushers are good for hard and rough materials. They work best after the first crushing step. They do not work well with concrete that has lots of rebar. ONA’s cone crusher parts and high manganese liners save energy and last long. You can trust ONA’s machines for steady results.

Impact crushers break concrete by hitting it with a fast rotor. The concrete hits plates and breaks into small pieces. This crusher makes more fine and cube-shaped pieces. These are good for road base and new concrete. There are different kinds of impact crushers. Some are mobile and can be used at the job site. ONA’s impact crusher parts and blow bars are made from strong materials. They last longer and work better.

Mobile crushers let you crush concrete at your work site. Portable crushers save time and money. You do not need to move concrete far. You can move these machines from one job to another. ONA’s mobile crushers do many crushing jobs in one machine. They help you work in a green and flexible way. ONA gives help with setup, care, and spare parts for all crushers.

Tip: Using ONA’s OEM spare parts and high manganese liners helps your concrete crusher last longer and work better.

ONA’s worldwide team and supply network make sure you get the right parts and help for your concrete crushers.

Knowing how concrete crushers work helps you use them better. You can turn big pieces of concrete into smaller ones. This makes work faster and cuts down on waste. It also helps you recycle more at your job site.

Crushing concrete uses strong machines. Each machine type breaks concrete in its own way. You can see how they work in the table below:

Crusher Type | Working Principle | Mechanism Description |

|---|---|---|

Jaw Crusher | Material crushed by periodic extrusion between movable and fixed jaws | Compression: Squeezing material between two surfaces |

Cone Crusher | Rotating cone squeezes material in a fixed cavity | Squeezing: Material crushed by a rotating cone |

Impact Crusher | Material struck by high-speed rotor and collides with impact plates | Impact: Breaking material by high-speed collision |

Roll Crusher | Double rollers rotate to squeeze materials | Compression: Squeezing material between two rotating rollers |

Jaw crushers use a moving jaw to press concrete. The jaw pushes it against a still jaw. This crushes the concrete into smaller bits. Cone crushers have a spinning cone inside a bowl. The cone squeezes the concrete until it breaks. Impact crushers have a fast rotor with blow bars. The rotor hits the concrete and breaks it on plates. Each crusher works best for certain jobs and types of concrete.

ONA’s crushers use strong materials like high manganese steel. These parts last longer and can handle hard work. ONA’s team checks every part for quality. They use special tools to look for problems. This makes sure your machine works well and lasts longer.

You need to follow steps to crush concrete safely. Here is an easy guide:

Put on safety gear like goggles, gloves, and a dust mask.

Take out metal like rebar and other trash from the concrete.

Break big chunks into smaller ones with hammers or breakers.

Put the small pieces into the crusher. Pick the right crusher for your job.

Use screens to sort the crushed concrete by size.

Spray water to keep dust down while crushing.

Move the sorted pieces with a conveyor or forklift.

Magnets and screens help pull metal out of the crushed concrete. This makes the end product cleaner and safer to use again. ONA’s machines let you change the size of the output. You can get small gravel or bigger pieces. ONA’s team checks every part before sending it out. They look at jaw crusher parts, blow bars, and liners to make sure they work well.

Tip: Keep your crusher in good shape by greasing and checking bolts. This helps your machine last longer and work better.

You might wonder how an impact crusher works. First, you feed concrete into the machine. The rotor spins very fast. Blow bars on the rotor hit the concrete hard. The force throws the concrete against plates inside. The concrete breaks into smaller pieces. These pieces bounce around until they are small enough to leave the machine.

You can change the rotor speed and the space between plates. This lets you pick the size and shape of the crushed concrete. Impact crushers are good for making fine, even pieces. You often use them after jaw or cone crushers for more crushing.

ONA’s impact crushers use strong blow bars and tough liners. The team tests each part to make sure it is strong. ONA uses special tools and checks for quality. This makes sure your machine works well and is safe.

Note: ONA’s engineers help with setup, fixing, and care. You can ask them for help with your crusher.

Crushing concrete with new machines helps recycling and cuts waste. ONA’s focus on quality and service helps you get the best from your equipment.

Concrete crushing can help you save a lot of money. Using mobile crushers at your site means you do not buy new aggregate. You also do not pay to move debris away. This way, you spend less on labor, fuel, and transport. Crushing concrete where you work helps you finish faster. It keeps your project on time. Recycling concrete costs about $7.50 for each ton. Dumping it in a landfill can cost up to $105.00 per ton. That is a big difference in price. You also skip landfill fees and use fewer new materials. Some contractors make extra money by selling crushed material. Others offer crushing services to others. ONA’s crusher liners and spare parts help your machines work well. This way, you get the most value from every job.

Crushing concrete is good for the environment. When you recycle concrete and asphalt, you keep waste out of landfills. This saves space and lowers pollution risks. Crushing concrete means you need less new cement. This helps cut down carbon emissions. You also save natural resources like sand and gravel. The table below shows some important environmental benefits:

Environmental Benefit | Explanation |

|---|---|

Reduction in Landfill Use | Concrete crushing turns waste into reusable aggregates, saving landfill space and lowering environmental risks. |

Reduction in Carbon Emissions | Recycling concrete means less new cement is needed, which lowers greenhouse gas emissions. |

Resource Conservation | Using recycled aggregates saves natural resources and energy. |

By choosing concrete crushing, you help make the future greener.

Concrete crushing gives you many choices. You can crush concrete with rebar, bricks, rocks, or even asphalt. Crushers can handle many kinds of materials. This means you can use them for lots of jobs. You can recycle concrete from buildings, roads, and bridges. You can also crush concrete washout and slurry waste. This lets you make recycled aggregates for new building, landscaping, or road base. You can use jaw crushers, cone crushers, or impact crushers for your needs. ONA has many crusher parts and gives technical support. You always have the right solution for your job.

Tip: Concrete crushing helps you make aggregate for building and high-quality cubical aggregates for many uses.

You need to choose the best crusher for your job. Think about how big your project is and what kind of concrete you have. Jaw crushers are good for big pieces. Cone and impact crushers are better for smaller, even pieces. Mobile crushers are great if you need to move from place to place. Look at your budget and how much material you need to crush. ONA’s team can help you pick the best crusher. They also give after-sales service. You get expert advice, fast delivery, and support from a trusted company.

ONA is known for great customer service and technical help. You get support before, during, and after you buy. ONA’s engineers help you pick the right equipment and give solutions for your needs. With ONA, you can trust your concrete crushing project will go well from start to finish.

Many people think concrete crushers are only for large demolition sites. In fact, you can use them for small projects, too. Some believe all crushers work the same way. This is not true. Each type, such as jaw, cone, and impact crushers, has a unique crushing method. Understanding impact crushers helps you see why they are great for making fine, even materials. Another myth is that concrete crushing is unsafe. When you follow safety rules and use the right equipment, you can keep your site safe and efficient.

You must always put safety first when using a concrete crusher. Here are some important safety steps:

Check that all guards and emergency stops work before you start.

Wear personal protective equipment like hard hats, safety glasses, and steel-toed boots.

Keep your work area clean and free of debris.

Never clear blockages while the machine is running.

Train everyone on emergency procedures and safe operation.

Regular maintenance keeps your crusher working well. Follow these steps:

Set a daily, weekly, and monthly maintenance schedule.

Lubricate moving parts to reduce wear.

Inspect wear parts like crusher liners and blow bars for damage.

Keep the crusher clean to prevent clogging.

Listen for unusual noises and check for loose belts or bolts.

Tip: ONA’s technical team can help you with maintenance plans and provide high-quality spare parts.

Choosing the right crusher and parts depends on your project needs. Think about the hardness of your material, the size you want after crushing, and how much you need to process each day. Jaw crushers work best for large, hard pieces. Cone crushers are good for secondary crushing. If you need to handle mixed materials or want more control over the final size, an impact crusher may be the ideal impact crusher for your project. Mobile crushers give you flexibility if you move from site to site. ONA offers expert advice and a wide range of crusher parts, so you always get the best fit for your job.

You now know how crushers turn concrete waste into new materials you can use again. These machines help you save both time and money because you can recycle right where you work. By doing this, you also help the environment. You send less trash to landfills and lower carbon emissions. ONA has jaw crusher parts, blow bars, and spare parts to keep your machines working well. If you need help or have questions, ONA’s technical team can help you pick the best option for your project.

You can crush concrete, bricks, asphalt, and stone. Some crushers can also break concrete with rebar inside. ONA’s concrete crusher parts work with many materials. You can use screens to sort the crushed pieces for different jobs.

Check jaw plates, blow bars, and liners often for damage. Replace them if you see cracks or they look very worn. Using ONA’s strong crusher wear parts helps your machine last longer and work better.

Yes, you can use mobile concrete crushers on small sites. These machines fit in small spaces and are easy to move. You save time and money by crushing material right where you work.

ONA gives you strong crusher parts, quick delivery, and expert help. You get help picking parts, setting up, and taking care of your machine. ONA’s team makes sure your concrete crushing project goes well from start to finish.