- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-07-18 Origin: Site

A jaw crusher is a strong machine that breaks big rocks into small pieces. You can think of a jaw crusher like a nutcracker or your own jaw. It uses two plates. One plate stays still and the other moves. The plates crush materials between them. This simple design makes jaw crushers important in many jobs. You will see jaw crushers in mining. They help get minerals out of rocks. In construction, they crush concrete, asphalt, and bricks. These machines also help with recycling and demolition. They turn waste into material you can use again. Many companies need jaw crushers, cone crusher parts, and other crusher accessories. These tools help their work go well.

Jaw crushers crush big rocks into small pieces. They use two plates. One plate stays still and the other moves. This helps crush things fast and well.There are two main types of jaw crushers. Single-toggle crushers are simple and work well with soft materials. Double-toggle crushers use more force for hard rocks.Jaw crushers are used in mining, construction, and recycling. They also help make aggregates. They save time and money. They help recycle old materials.ONA sells strong jaw crushers parts. Their experts help you pick, fix, and care for your machine. This makes your jaw crusher last longer.Jaw crushers are cheap to use and last a long time. They can do many jobs. They help you work faster and better with tough materials.

A jaw crusher helps break big rocks into smaller pieces. It uses two jaws to crush things. One jaw stays still. The other jaw moves back and forth. The moving jaw pushes the material against the fixed jaw. This crushes the material into smaller bits. There are different types of jaw crushers. They are called Blake, Dodge, and Universal. The difference is where the pivot point is. Blake jaw crushers can be single-toggle or double-toggle. Single-toggle crushers move in an oval shape. They work best with softer materials. Double-toggle crushers have a more complicated motion. They are better for hard and rough materials. All types use the same idea. They crush things by pressing them between two jaws.

A jaw crusher has many important parts. Each part helps the machine work. Here is a table that shows the main parts and what they do:

Component | Function |

|---|---|

Main Frame | Holds all the parts and takes the crushing force. |

Fixed Jaw Plate | Stays in place; grips and crushes material with strong steel. |

Movable Jaw Plate | Moves to crush material; attached to a pivot; made to last. |

Eccentric Shaft | Changes spinning motion to back-and-forth jaw movement. |

Pitman | Connects the shaft to the moving jaw; helps the jaw move; has smooth bearing points. |

Toggle Plates | Link pitman to frame; help lift and protect; break if overloaded. |

Flywheels | Store energy for smooth running; help the engine move. |

Setting Mechanism | Changes the space between plates to control size; uses shims or hydraulics. |

Each part works together to help the jaw crusher do its job.

ONA gives you more than just a jaw crusher. ONA is a top maker and seller of jaw crushers and parts. Their team has lots of experience. ONA checks every product carefully. They use special tools to make sure everything is good. You can get many products like jaw crusher parts, liners, and spares. ONA’s engineers help you pick the best parts for your job. ONA cares about quality and helping customers. That is why many people trust ONA for their crushing machines.

You may wonder how jaw crushers break big rocks. The jaw crusher working principle is easy to understand. You put material into the top of the machine. The movable jaw goes back and forth. It pushes against the fixed jaw. This makes pressure and sometimes friction. The material gets squeezed and breaks apart. The jaw crusher working principle uses force to crush hard things. You can change the gap between the jaws. This controls the size of the pieces that come out. This idea makes jaw crushers good for many jobs.

ONA builds every jaw crusher using this idea. Their engineers use special tools to check each part. ONA’s team looks at every detail. You get a machine that works well and lasts longer. The jaw crusher working principle helps you crush tough things with less work.

When you use a jaw crusher, crushing starts right away. The movable jaw pushes the material against the fixed jaw. The force breaks the material into smaller pieces. This keeps happening until the pieces are small enough to fall out.

Let’s look at the forces used in the crushing process:

Jaw Crusher Type | Mechanical Forces Involved | Description |

|---|---|---|

Single-toggle | Pressure and friction | The movable jaw moves in an oval path. It uses both pressure and friction to crush material. |

Double-toggle | Pressure only | This type uses only pressure. It is better for very hard materials and lasts longer. |

Single-toggle jaw crushers use pressure and friction. Double-toggle jaw crushers use only pressure. Both types use the same main idea, but the forces are a little different. ONA’s team can help you pick the right type for your job. They also have wear parts and cone crusher parts to keep your machines working.

ONA’s machines are special because of careful design. Each jaw crusher gets tested a lot. ONA uses special tools to check every part. You get a product that meets high standards and works well.

Think about how your jaw works when you eat food. Your lower jaw moves up and down. It crushes food against your upper jaw. A jaw crusher works in a similar way. The movable jaw is like your lower jaw. The fixed jaw is like your upper jaw. The material gets stuck between the jaws. It breaks apart as the movable jaw presses it.

Another way to think about it is a nutcracker. You put a nut between the two arms. When you squeeze the handles, the nut cracks open. Jaw crushers use this same idea to break rocks and other hard things.

ONA’s engineers make each jaw crusher to copy this action. They use strong materials and careful measurements. You get a machine that works like your jaw—strong, reliable, and efficient.

Tip: If you want to know how jaw crushers work in different jobs, ONA’s team can help you. They give expert advice and custom answers for your needs.

Let’s compare jaw crushers to other crushers:

Factor | Jaw Crusher | Cone Crusher |

|---|---|---|

Crushing Principle | Simple compression action | Complex crushing with wobbling mantle |

Feed Size | Handles bigger feed sizes (up to 1,500 mm) | Needs smaller feed sizes (up to 350 mm) |

Reduction Ratio | 4:1 to 9:1 | 6:1 to 8:1 |

Production Capacity | Higher (200-1,000 tons/hour) | Lower (100-750 tons/hour) |

Energy Consumption | Lower (1-2 kWh/ton) | Higher (2-4 kWh/ton) |

Crushing Stage | Used for primary crushing | Used for secondary and tertiary crushing |

Product Quality | Coarser, less even | Finer, more even and cubical |

Material Suitability | Hard, rough materials, not sensitive to moisture | Medium to hard materials, needs steady feed |

Maintenance | Simple design, fewer parts to replace | More complex, higher maintenance costs |

Jaw crushers work best for first crushing. They handle big pieces and use less energy. Cone crushers are better for finer, more even products. ONA has both jaw crusher and cone crusher parts, so your equipment stays in good shape.

ONA’s focus on quality means you get a jaw crusher that works well and lasts longer. Their machines help you save time and money, making your job easier.

Jaw crushers are used in many fields. You see them in mining, construction, making aggregates, and recycling. These machines help break tough materials. They make hard jobs easier. Let’s see where jaw crushers are used and how ONA helps.

Jaw crushers are the first machines used in mining and quarrying. They break big rocks and ores into smaller pieces. This makes it easier to process them later. In 2023, jaw crushers broke over 10.6 billion metric tons of rock. This shows how important they are for crushing ore and stone. Jaw crushers are trusted for the first step in ore plants. They handle hard and rough materials every day.

In construction and recycling, jaw crushers turn waste into useful stuff. You can use them to crush old buildings and concrete. Here is what jaw crushers do in these jobs:

Crush concrete and debris into small pieces to use again.

Take out metal, wood, and trash before crushing, often with magnets.

Sort clean concrete by size to make crushing easier.

Make recycled concrete aggregate (RCA) for new roads and buildings.

Save money and help the planet by recycling at the site or plant.

Jaw crushers make good recycled materials. You get strong RCA for new work. You also help the earth by keeping waste out of dumps.

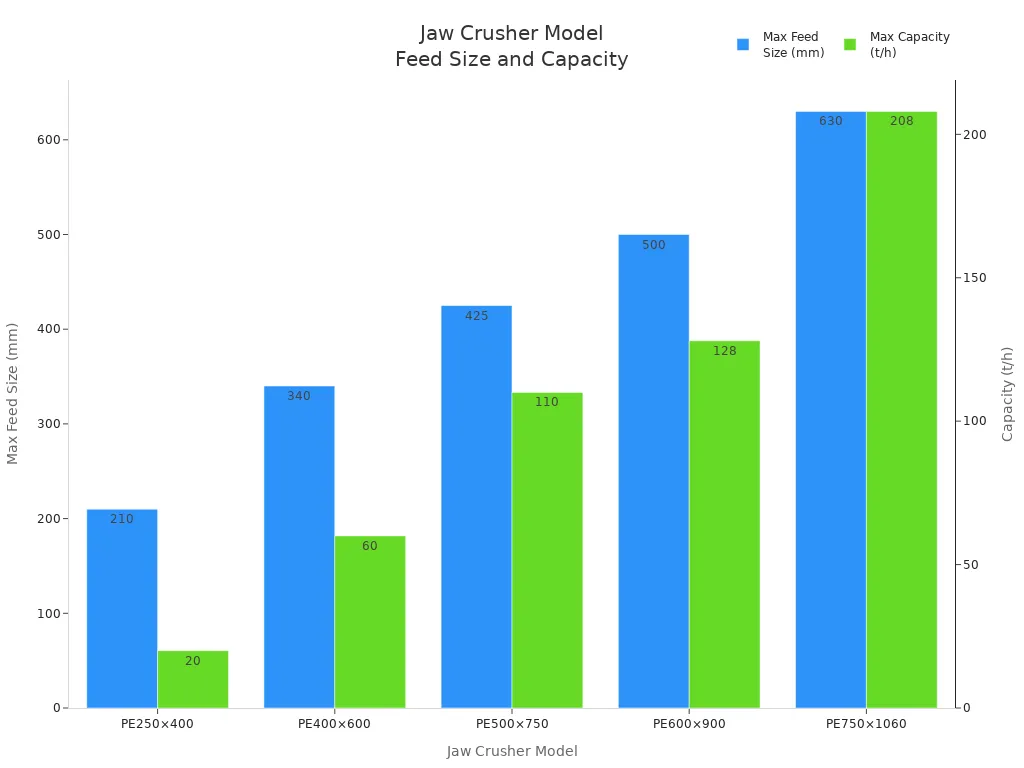

Jaw crushers are the first step in making aggregates. They take big pieces, up to 1,500 mm, and crush hard rocks like granite and limestone. The crushed rock is usually rough and may need more crushing. Jaw crushers give even sizes, low wear, and low costs. Here is a table with some models and what they can do:

Model | Feeding Opening Size (mm) | Max Feed Size (mm) | Discharge Opening Size (mm) | Capacity (t/h) |

|---|---|---|---|---|

PE250×400 | 250×400 | 210 | 20-60 | 5-20 |

PE400×600 | 400×600 | 340 | 40-100 | 16-60 |

PE500×750 | 500×750 | 425 | 50-100 | 40-110 |

PE600×900 | 600×900 | 500 | 75-160 | 64-128 |

PE750×1060 | 750×1060 | 630 | 80-140 | 51-208 |

You can see jaw crushers work for small and big jobs.

ONA has helped mining, quarrying, construction, and recycling for years. You get more than just machines from ONA. They give support after you buy, technical help, and custom answers for your needs. Their team helps you pick the right jaw crushers, cone crusher parts, and wear parts. ONA’s experts help you from choosing to setting up and fixing. You can trust ONA to keep your machines working well, no matter the job.

Tip: ONA’s team can help you fix special problems in your ore plants or recycling jobs. Ask them for advice and good service.

When you pick jaw crushers, you get many good things. These machines help you finish work faster. They save money and can crush many kinds of materials. Let’s see the main reasons jaw crushers are helpful and how ONA’s products are special.

Jaw crushers break big rocks fast. You can crush a lot of material quickly. New jaw crushers have smart designs and strong parts. This helps your work go smoothly. You can change the size of the crushed pieces. Mobile jaw crushers let you crush right at the job site. This saves time and cuts down on moving costs. ONA’s jaw crushers have smart controls and watch the machine in real time. This means they work well and stop less often.

Tip: ONA keeps lots of jaw crusher parts ready to ship. You do not have to wait long for new parts or wear parts.

You want machines that last a long time. Jaw crushers are simple and strong. They work well even when the job is hard. ONA uses top materials and checks every part before sending it out. Their team uses special tools to test for strength and safety. If you take care of them, jaw crushers can last for years. ONA’s careful checks help you avoid trouble and keep your machines working.

Key Feature | ONA Advantage |

|---|---|

Strong Materials | High-manganese steel for jaw plates and liners |

Quality Control | Full inspection with advanced measuring equipment |

Long Service | Durable parts, easy to replace and maintain |

Jaw crushers are used in many jobs. You can use them in mining, building, or recycling. They crush hard rocks, ores, concrete, and glass. You can change the opening to get the size you want. ONA has many types of jaw crushers and cone crusher parts. This means you can use one machine for many tasks.

Crush granite, limestone, or old concrete

Change settings for different sizes

Use in fixed places or move them to new sites

Jaw crushers help you save money. They cost less to buy and fix than other crushers. They use less energy for the first crushing step. You can put big pieces in, so you need fewer machines. ONA makes parts quickly and keeps prices low. You get machines that work well and save you money over time.

Note: Jaw crushers are a smart pick if you want to spend less and save more in the long run.

If you want to know more about jaw crushers or need help picking parts, ONA’s team can help you.

There are two main types of jaw crushers. These are single-toggle and double-toggle. Each type works best for certain jobs. Knowing the differences helps you pick the right one.

A single-toggle jaw crusher has one toggle plate. It also has an eccentric shaft at the top of the moving jaw. The moving jaw swings in a curve. It pushes material against the fixed jaw. This is like how a nutcracker works. The single-toggle design is simple. It has fewer parts. This makes it easy to fix and adjust. These crushers can take in big pieces. They are good for first crushing in mining and building. The jaw plates are made from strong steel. They last a long time. You can use single-toggle crushers for soft stones and hard rocks. They also work for concrete with rebar. Many people use them with screening plants to get the right size.

Tip: If you want a crusher that is easy to set up and fix, pick a single-toggle jaw crusher.

A double-toggle jaw crusher has two toggle plates. It also has a pivot point. The eccentric shaft is behind the moving jaw. This design makes the jaw move up and down. Double-toggle crushers make more crushing force. They are best for very hard and rough rocks. These include granite and iron ore. These machines are heavier and have more parts. They do not need fixing as often but are harder to service. Double-toggle crushers are used in big mining jobs. They give high power and last a long time.

You can see the main differences in this table:

Feature | Single Toggle Jaw Crusher | Double Toggle Jaw Crusher |

|---|---|---|

Toggle Mechanism | One toggle plate | Two toggle plates |

Jaw Motion | Moves in an oval shape | Moves straight up and down |

Crushing Force | Medium | High |

Best For | Softer to medium-hard materials | Very hard, rough rocks |

Maintenance | Cheaper, needs more often | Costs more, needs less often |

Capacity | 200–300 T/H | Up to 600 T/H |

ONA helps you pick the right jaw crusher. They give advice, show diagrams, and visit your site. For example, ONA helped a customer in Indonesia. The customer saw a single-toggle crusher working. They chose it because it was easier and had better capacity. ONA sells parts for both types. This includes wear parts and cone crusher parts. ONA’s engineers help you get the best machine for your job.

You now know what a jaw crusher does, how it works, and why it matters in mining, construction, and recycling. ONA gives you strong machines, expert support, and real cost savings. When you choose ONA, you get reliable jaw crusher and cone crusher parts, plus help with every step.

Factor | Explanation |

|---|---|

Robust Construction | ONA builds jaw crushers for tough jobs and long life. |

After-Sales Support | You get fast service, spare parts, and training. |

Many customers say ONA’s portable jaw crusher saves money and boosts efficiency.

You can find manuals, videos, and more on the ONA website or talk to their technical team for answers.

Jaw crushers can crush hard rocks and ores. They also crush concrete and recycled materials. You can use them for granite, limestone, and building debris. ONA has jaw crusher parts and high manganese liners. These parts help the machine work better for special jobs.

Check the wear parts often to keep the crusher working. Change jaw plates and liners when they get worn out. Make sure to add oil to moving parts. ONA gives you crusher accessories and technical help. This support helps your machine last longer and run well.

You can use jaw crushers with cone crushers and impact crushers. They also work with screening equipment. This setup helps you get the right size and shape. ONA has cone crusher parts and impact crusher parts. These parts help you build a full crushing system.

Go to ONA’s official website to find jaw crusher parts. You can also get wear parts and crusher accessories there. ONA ships parts fast and gives expert advice. They also help you after you buy your equipment.