- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-07-21 Origin: Site

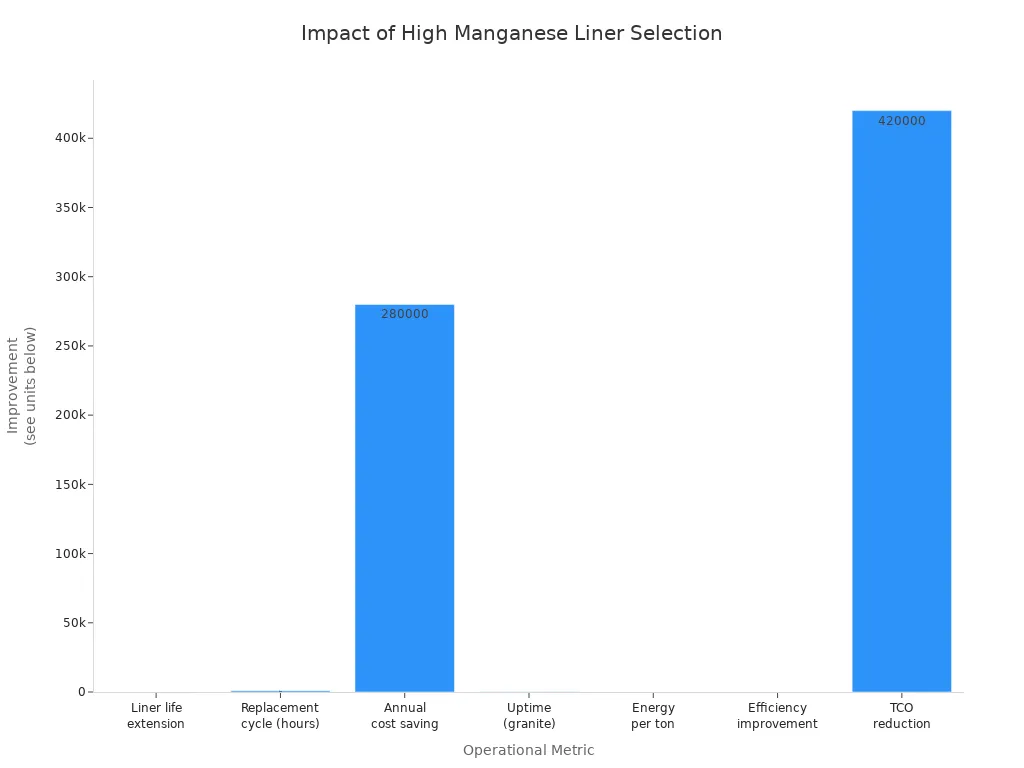

The wear life of a high manganese liner depends on a few main things. These include manganese content, steel composition, and the working environment. Industry data shows that knowing these things helps companies make high manganese steel liners last longer. This means less maintenance and more time when equipment works. For example, new high manganese steel liners can last up to 30% longer. They can also cut down on sudden shutdowns by almost 30%. ONA knows a lot about high manganese steel. ONA offers many high manganese liner products with 13%, 18%, and 22% manganese. These show the best ways to get strong and long-lasting liners. Picking the right high manganese liner and taking care of it can make equipment work 35% better. It can also lower costs, as mining case studies show.

Picking the right amount of manganese and alloy mix makes liners stronger. This helps them last longer in hard jobs.

Good heat treatment and grain control keep liners tough. They also help liners get harder as they are used. This lowers wear and stops them from breaking.

High manganese liners fight wear by getting harder when hit or rubbed. This can make them last up to 30% longer.

Checking liners often and matching them to the crusher and material helps stop sudden breaks. It also makes the machine work better.

Using data and expert help to choose and care for liners saves time. It also cuts costs and keeps machines working well.

Manganese is very important for high manganese steel liners. The chemical makeup helps the liners work in tough places. If the manganese is about 14%, it keeps the austenitic microstructure stable. This structure makes the steel bend without breaking and get harder when used. When force is put on the steel, austenite turns into martensite. This makes the liner stronger and helps it last longer. Hadfield steel has about 13% manganese and is a well-known type. ONA sells liners with 13%, 18%, and 22% manganese. This lets people pick what works best for them. The right mix helps the liner handle hits and rubbing. This makes it last longer and means less time fixing it.

High manganese steel often has other alloying elements to make it better. Chromium and molybdenum are two common ones.

Chromium makes the steel harder and helps it last longer. It also makes the grain smaller and the steel tougher.

Molybdenum helps the steel get hard deep inside and makes the grains even smaller. This makes the steel strong and tough.

Using both chromium and molybdenum can make liners last twice as long as normal ones.

A table below shows what these elements do:

| Alloying Element | Effect on Strength | Impact on Wear Life | Microstructural Mechanism |

|---|---|---|---|

| Chromium | Makes steel harder and stronger | Helps liners last longer | Makes small carbides form |

| Molybdenum | Makes steel stronger and tougher | Makes liners last longer | Makes grains smaller, slows carbide forming |

| Cr & Mo Combined | Makes steel very strong and tough | Liners last twice as long | Makes carbides, makes grains smaller |

Picking the right mix of these elements makes liners stronger and last longer.

Microalloying makes high manganese steel liners even better. Small amounts of titanium, niobium, and vanadium help control grain size. This makes the steel tougher and helps it last longer. Boron, even in tiny bits, can make the liner last much longer. But it is hard to use in making steel. Nickel makes the steel bend more and be tougher. Molybdenum helps the steel get harder again after use. Rare earth metals make grains smaller and help the liner take hard hits. But they cost more and are not always easy to get. Microalloying makes the steel’s structure very fine. This helps the liner take hits and rubbing better. These changes help high manganese steel liners work well in today’s crushing machines. ONA’s liners use these ideas to work well and last a long time.

Heat treatment changes how high manganese steel liners work. Makers heat the steel until it gets very hot. Then, they cool it down fast. This keeps the austenitic microstructure in the steel. That is what lets the steel get harder when used. If heat treatment is not done right, carbides can form. These carbides show up at the edges of the grains. They make the liner easy to break and not last as long. Good heat treatment keeps the steel tough. It helps the liner take hard hits. ONA uses careful temperature checks to keep the right structure. This makes the liner strong.

Grain structure is very important for how long liners last. Using the right materials and melting them at the right heat makes small, even grains. This stops carbides from building up at the grain edges. If carbides gather, the liner gets weak and cracks more easily. A steady austenitic microstructure lets the liner get harder when used. This helps it fight wear. Titanium and vanadium help keep the grains small and even. These steps make the liner stronger and help it last longer.

Note: Keeping the right grain structure in high manganese steel is very important for strength and lasting a long time.

Makers use many checks to make sure each liner is good:

Test certificates show the chemistry, size, and heat treatment are right.

Chemistry checks look at carbon, manganese, and other elements.

Size checks make sure the liners fit crushers well.

Heat treatment checks use special tests to see the austenitic microstructure.

Metallurgical checks look at early breaks to find out why.

These steps help every liner stay strong and last a long time. ONA checks quality to make sure each liner works well in tough jobs.

Abrasion is a main reason high manganese liners wear out. When mineral pieces move between metal parts, they make sharp edges. These edges scratch and slowly wear away the liner. This causes small cracks and bends in the liner. Over time, the liner loses some of its material. Heat treatment helps stop abrasion by making carbide particles stronger in the steel. This makes the liner harder and better at fighting scratches. Operators see that good heat treatment helps liners last longer in crushers. Even with these changes, abrasion still makes liners wear out, especially when minerals keep moving all the time.

Impact forces are very important for how high manganese liners work. These liners get hit again and again by rocks and other things. The steel’s special structure lets it take in energy from hard hits. This stops the liner from breaking or losing its shape. The surface gets harder each time it is hit. This helps the liner fight off more wear. In tough jobs like mining, liners need to handle hard hits to last longer. Good heat treatment and the right liner size help stop the liner from getting too brittle. But if the liner gets hit too much, it can spread out. This makes it harder to remove and can hurt the equipment if not watched.

Note: High manganese liners do not break easily when hit, but workers should check for spreading or too much stress to stop sudden problems.

Work hardening helps high manganese liners last longer when used a lot. When rocks press or hit the liner, the top layer gets harder. The hardness can go from about 25 Rockwell up to 60 Rockwell. This makes the liner better at fighting wear and last up to 30% longer. Operators get good work hardening by running machines at low power first. Then, they slowly turn up the power. Feeding the machine the right way helps the liner get harder and wear evenly. Not feeding it right can make the liner break or fail. This helps the liner work well even in tough places.

Load and force are very important for liner wear. When crushers work, liners get rolled and slid on. The steel gets hard, then small bits break off. This keeps happening as new layers show up and get hard again. How much load there is changes how the steel gets hard. At low loads, both dislocation slip and twinning make the liner stronger. When the load gets higher, dislocation slip is the main way the steel hardens. Pressures over 0.6 MPa make the steel hardest. This gives the best wear resistance. Operators see different wear marks as the load changes. Higher loads make the liner harder but can also cause more damage from stress.

Tip: Keeping the load just right helps the liner last longer and stops sudden breaks.

The kind of material in the crusher changes liner wear. Hard, rough pieces do the most harm. For example, big gravel pieces wear liners down fast. The main wear types are abrasive and adhesive. But abrasive wear happens the most. Heavy loads with hard pieces make the liner lose material faster. Sometimes, small rough bits stick to the liner and give a little protection. But this does not help much. Corrosive stuff can make wear worse. But most of the damage comes from things rubbing on the liner. Operators should watch for changes in the material. This can mean the liner will wear out faster.

Different crushers and ores change how liners work. Crusher types like jaw, cone, or gyratory put different stress on the liner. Ore size, hardness, and friction also matter. Big pieces can jam the crusher and wear the liner unevenly. The crusher’s shape and design change how force moves through the liner. Changing things like speed and closed side setting can help balance the force. This can lower wear. When operators match the liner to the crusher and ore, they get better results and longer liner life.

Operators should check crusher settings and ore often. This helps liners work well and last longer.

Studying how long a high manganese liner lasts helps operators pick better parts. Teams look at wear marks and service records to see how liners work in real jobs. This helps them find out which liners last longer and which ones need to be changed more often. Operators use digital wireless sensors to check liner thickness while machines run. These sensors show live updates on how much metal is gone. Teams also use laser scans and hands-on checks to spot places that wear out faster.

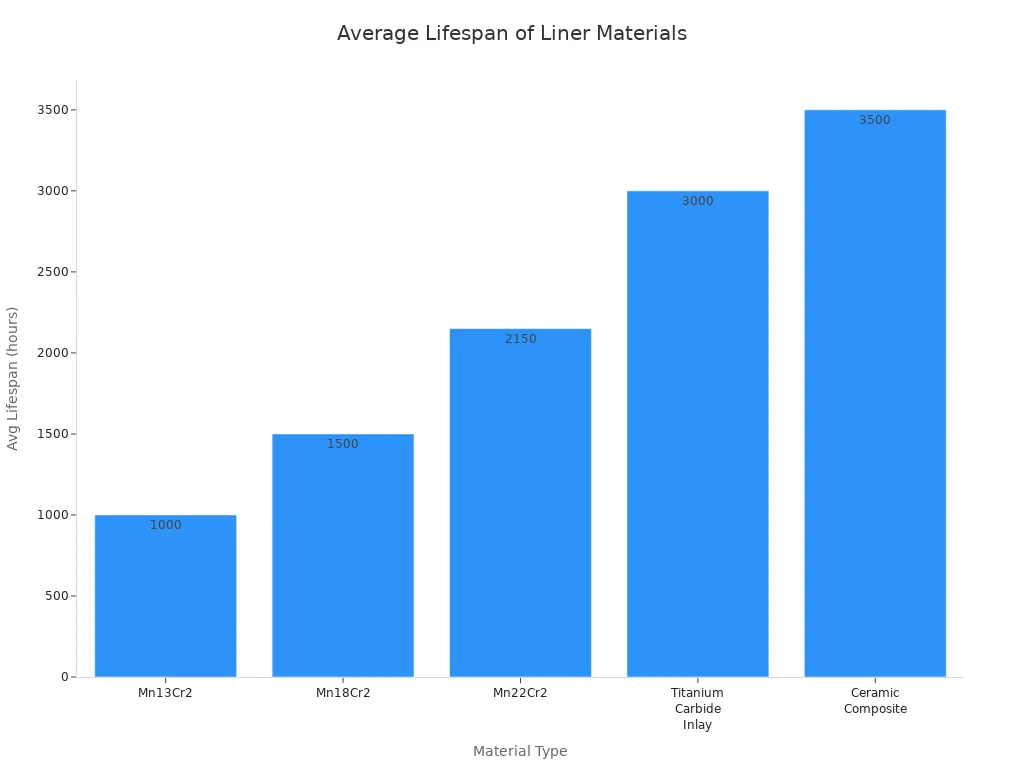

A table below shows how long different manganese liners and new materials last:

| Material Type | Hardness (HRC) | Wear Resistance Index (relative to Mn13Cr2) | Impact Resistance | Expected Lifespan (hours) |

|---|---|---|---|---|

| Mn13Cr2 | 18-22 | 1.0 | High | 800-1200 |

| Mn18Cr2 | 22-25 | 1.5 | Moderate | 1200-1800 |

| Mn22Cr2 | 25-28 | 2.0 | Lower | 1800-2500 |

| Titanium Carbide Inlay | 58-62 | 3.5 | Low | 2500-3500 |

| Ceramic Composite | 60-65 | 4.0 | Very Low | 3000-4000 |

At a granite quarry, workers switched from regular manganese steel to Mn22Cr2 with titanium carbide. This made the liner last from 600 up to 1900 hours. The longer life meant less downtime and saved money. Looking at this kind of data helps companies pick the best liner for each job. ONA helps by offering many liner choices and keeping lots in stock for fast shipping.

Note: Checking wear data and service records often helps people pick better products and makes liners last longer.

Performance metrics help workers see how well a high manganese liner works over time. Important things to check are wear rate, downtime, and how often liners need to be replaced. High manganese liners with 11-14% manganese are tough and fight off scratches. These liners get harder as they are used, so they wear out slower and last longer. The hardness after use tells more about wear resistance than the starting hardness.

Operators notice that custom high manganese liners cut downtime by up to 30%. These liners last longer and do not need to be changed as much. Their design also makes them easier to put in, so fixing them is faster. Using good manganese steellowers the wear rate and how often you need new liners. This saves money and keeps machines running longer.

A table below compares how different liner materials perform:

| Performance Metric | High Manganese Steel (11-14% Work-Hardening) | Premium Chromium Carbide Overlay | RapidFlow Carbide Overlay (Smooth Surface) |

|---|---|---|---|

| Wear Rate | Moderate to low in impact-heavy applications | High abrasion resistance but less impact toughness | High abrasion resistance with reduced carryback (up to 80% reduction) |

| Downtime | Reduced by up to 30% with custom manganese steel parts | Moderate, depends on brittleness under impact | Significantly reduced due to less material sticking and easier flow |

| Replacement Frequency | Lower, due to extended wear life in impact environments | Higher in impact conditions due to brittleness | Lower, due to reduced carryback and abrasion |

| Application Examples | Crusher liners, impact bars, hammers, buckets | Coal mill liners, hoppers, chutes | Flow systems requiring reduced carryback |

| Key Benefits | Toughness and ductility absorb repeated impact energy, balancing wear resistance and durability | High hardness and abrasion resistance but less impact toughness | Smooth surface reduces friction and material buildup, improving uptime |

Studying these numbers helps workers match the right liner to each job. Teams use different ways to collect and check wear data:

Digital wireless sensors give live thickness readings.

Discrete Element Modelling (DEM) shows wear patterns from crushing.

Laser scans check real wear against what models predict.

Hands-on checks and lasers find spots that wear out fast.

Real data helps engineers make liners thicker where needed.

Workers also think about what kind of material is being crushed and how rough it is. They pick the manganese content that fits the job best, like 13%, 18%, or 22%. This helps balance strength, cost, and how well the liner works. ONA’s support team helps customers look at service data and pick the best liner. Their big stock means customers get the right part fast, so machines keep working.

Tip: Checking liner data and picking the best one for each job can make liners last longer, cut downtime, and help crushers work better.

High manganese liners can fail in a few ways in crushers. The most common problem is fracture. Fractures start as tiny cracks on the liner’s surface. These cracks get bigger as the liner works under heavy loads. After a while, the cracks join and cause a full break. Fractures can happen if big rocks hit the liner or if the steel gets too hard and brittle. Sometimes, weak spots in the liner make fractures show up. Operators often see cracks at the edges or corners. These cracks can make the liner fail suddenly. Fracture interface analysis helps engineers find where cracks began and how they spread. By looking at these patterns, teams can stop future fractures and make liners better.

Teams use different ways to study why liners fail. Visual inspection helps workers find early cracks and damage on the surface. They look for signs of breaks and check if the liner has changed shape. Ultrasonic testing finds hidden cracks inside the steel. This test shows where fractures might start before they get worse. Engineers also use dye penetrant testing to spot small cracks on the surface. Fracture interface analysis gives a close look at how cracks move through the liner. This helps teams learn why fractures happen and plan better repairs. Checking wear and fracture patterns often keeps equipment safe and working longer.

Optimization steps help high manganese liners last longer and fail less. Operators pick manganese steel liners because they fight wear well. They also choose liners that fit the job and machine needs. Teams use planned replacement programs based on hours and wear. This stops surprise fractures and cuts down on downtime. Watching for cracks and checking liner thickness helps find problems early. Engineers make liners better by changing their shape, thickness, and how they attach. Working with skilled makers like ONA means good quality and expert help. These steps, along with new research, help stop fractures and make liners work better.

Tip: Checking and improving liner wear patterns often can stop cracks and fractures before they cause big problems.

Key things that affect how long high manganese liners last are what they are made of, how they are heated, and how they are used. Studies show:

If the liner is not strong enough or does not get harder after small hits, it will not last as long.

Changing the mix of elements and how the liner is heated can make it last three times longer.

Different crusher parts need liners that are tough in special ways.

Checking liners often, getting help from experts, and using new materials like ONA’s liners help them last longer. Watching liners closely and picking the right ones means less time fixing machines and saves money. This also makes equipment work better and more often.

High manganese liners are very good at fighting wear. They get harder when rocks hit them again and again. This makes them last longer in crushers. ONA’s liners help machines stop less and cost less to fix.

More manganese makes liners tougher and helps them get harder. Liners with 18% or 22% manganese can take bigger hits. Operators pick the right amount for their crusher and the rocks they crush.

Operators should check liners often, at least every 500 hours. Checking early helps find wear or cracks before they get worse.

ONA has high manganese liners for many crusher brands. These include Metso, Sandvik, Symons, Trio, Terex, and Telsmith. Their stock fits most big crusher models.

Pick the right manganese content.

Use the right heat treatment.

Check liner thickness often.

Change liners before they wear out too much.

Doing these things helps machines work longer and better.