- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2026-01-27 Origin: Site

Ever wondered what keeps a jaw crusher running smoothly? The answer lies in the jaw plate. This crucial component ensures efficient material breakdown in industries like mining and construction.

In this article, we’ll explore the role of jaw plates, their materials, and key tips for selecting and maintaining them to maximize crusher performance.

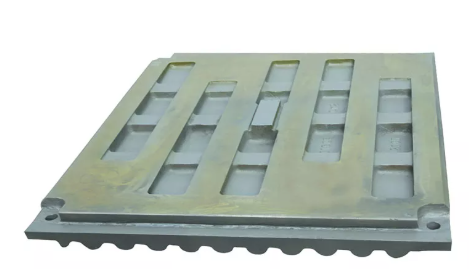

A jaw plate is a vital part of the jaw crusher, responsible for providing the surface against which raw materials are crushed. The basic operation involves a movable jaw that moves back and forth in an oscillating motion, compressing and breaking down materials against the fixed jaw plate. The two jaw plates work together to crush the materials in a gradual process, reducing them to smaller, more manageable sizes.

Jaw plates are subjected to extreme conditions during the crushing process, including high pressure and impact forces. These factors make the durability and wear resistance of jaw plates a critical consideration for maximizing crusher efficiency and minimizing downtime. Jaw plates are typically manufactured from various materials, such as high-manganese steel and alloy steel, to ensure they can withstand the wear and tear associated with the crushing process.

At ONA, our fixed jaw plates are manufactured using high-quality cast steel or forged steel to ensure strength, reliability, and long-lasting performance. The precision manufacturing of these jaw plates guarantees a perfect fit with the crusher model, optimizing the crushing process.

There are several different types of jaw plates, each designed to handle specific materials or crushing conditions. ONA provides a broad selection of jaw plates, offering a variety of tooth shapes and surface finishes to cater to various operational needs. Here are some common types of jaw plates:

1. Standard Jaw Plates: These are the most commonly used jaw plates and are designed for general-purpose applications where the material being crushed is not overly abrasive. They are typically used in primary crushing operations and are cost-effective for handling softer materials such as limestone.

2. Heavy-Duty Jaw Plates: For more demanding applications, such as crushing harder materials, heavy-duty jaw plates are used. These plates are thicker and more durable, able to withstand higher levels of pressure and impact. Heavy-duty plates are often used in secondary crushing and for materials like granite or ores.

3. Customized Jaw Plates: In some cases, businesses may require jaw plates that are tailored to meet specific operational needs. ONA offers custom jaw plates for crushers, which are designed based on unique specifications such as size, tooth shape, and material type. Custom jaw plates ensure that crushers can handle specialized crushing tasks more effectively.

By choosing the right type of jaw plate, businesses can optimize the efficiency of their crushers and reduce the frequency of maintenance and replacement.

Jaw plates are typically manufactured from materials that balance toughness, hardness, and wear resistance. The material chosen for a jaw plate impacts its ability to resist abrasion and wear, as well as its overall durability under extreme crushing conditions. Common materials used for jaw plates include:

● Manganese Steel: Manganese steel is by far the most common material used for manufacturing jaw plates. It is known for its excellent toughness, resistance to wear, and its ability to absorb and withstand high-impact forces. High-manganese steel grades such as MN13, MN18, and MN22 are specifically used for heavy-duty applications in jaw crushers.

● Alloy Steel: Some jaw plates are made from alloy steel, which offers greater hardness and wear resistance compared to regular steel. Alloy steel plates are typically used for highly abrasive applications where durability is paramount.

● Carbon Steel: Although less commonly used than manganese or alloy steel, carbon steel can be used in jaw plates for operations that do not require the extreme durability of manganese steel.

ONA's jaw plates are made from high-manganese steel, with MN13, MN18, and MN22 grades offering excellent wear resistance for processing a variety of materials, including ores, limestone, copper, and quartz.

The primary function of jaw plates is to break down raw materials by applying compressive force as the jaw crusher operates. The movable jaw plate moves back and forth, exerting pressure on the material that is squeezed between the fixed jaw plate and the movable plate. This crushing action reduces the size of large, solid materials, making them easier to process further or transport.

ONA's fixed jaw plates are designed with precision to ensure a perfect match with OEM specifications. This guarantees that the jaw plates will perform efficiently, ensuring smooth operation and optimized material processing. With high-manganese steel, these jaw plates provide excellent wear resistance, even under heavy operational conditions.

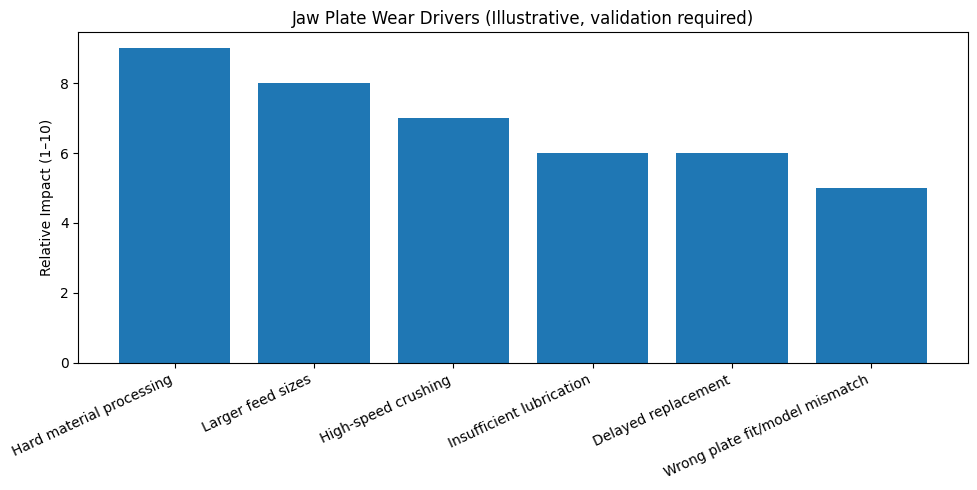

Given the high pressure and constant friction during the crushing process, jaw plates are prone to wear over time. The rate of wear depends on several factors, including the hardness of the materials being processed, the speed of the crusher, and the overall operating conditions.

The most common causes of wear and tear on jaw plates include:

Hard Material Processing: Crushing harder materials, such as granite or ores, places a greater amount of stress on the jaw plates, leading to more rapid wear and the need for more frequent replacements. This increased abrasion reduces the overall efficiency of the crusher, requiring more maintenance.

Larger Feed Sizes: The larger the material fed into the crusher, the greater the pressure placed on the jaw plates. This accelerates wear and can also lead to uneven crushing, further increasing the likelihood of jaw plate failure and reducing overall crusher performance.

High-Speed Crushing: Fast crushing speeds generate more heat, increasing the likelihood of jaw plate degradation due to the thermal stresses involved. This can cause warping or cracking of the plates, leading to diminished crushing capacity and frequent maintenance.

ONA's premium jaw plates are designed to last longer than standard plates, offering 20-30% longer service life. This is due to advanced heat treatment processes that improve wear resistance, ensuring that the plates can handle even the toughest materials.

Several factors can affect the lifespan of jaw plates:

Material Type: The harder the material being processed, the faster the jaw plates will wear. Hard materials like ores or granite require jaw plates made of tougher materials such as high-manganese steel to withstand the added strain, which is essential to extending the lifespan of the plates.

Operational Conditions: Crushing in extreme environments, whether from high pressure, abrasive materials, or high temperatures, can lead to faster wear on jaw plates. Operating the crusher beyond its capacity also accelerates the degradation of the plates.

Maintenance Practices: Regular inspection and timely replacement of jaw plates can significantly extend their service life. By addressing wear early and keeping the equipment properly maintained, companies can avoid costly breakdowns and maintain optimal crusher performance.

ONA's fixed jaw plates are designed to be corrosion-resistant and deformation-resistant, ensuring that they maintain their performance and structural integrity even in tough conditions.

When selecting jaw plates for your crusher, it's essential to choose the right plate for the type of material you plan to crush. The material's hardness and abrasiveness play a significant role in determining the right jaw plate for the job.

● Soft Materials: For materials like limestone, which are not overly abrasive, standard jaw plates made from manganese steel are sufficient. These plates are durable and can handle the crushing process effectively without unnecessary wear.

● Hard Materials: When dealing with tougher materials such as granite, iron ore, and ores, heavy-duty jaw plates made from high-manganese steel or alloy steel are necessary. These materials offer the strength and durability required to withstand the impact forces and abrasiveness associated with hard material crushing.

Each jaw crusher model has specific requirements in terms of jaw plate design, size, and fit. Using the wrong jaw plate can reduce crushing efficiency and increase wear, leading to unnecessary downtime and repair costs. It's crucial to ensure that the jaw plates for crushers are matched correctly to the model in use.

ONA’s jaw plates are precision-machined to ensure a perfect fit with your crusher, providing optimal performance and reducing the risk of inefficiency and excessive wear. These plates are manufactured to match OEM specifications, making them easy to replace without compromising the crusher’s overall function.

In certain cases, custom jaw plates may be required to handle specific crushing needs. ONA offers customized jaw plates that are tailored to the particular crushing application, ensuring a perfect fit and optimal performance for specialized materials or challenging operating conditions.

Custom jaw plates are especially useful in applications where standard jaw plates cannot handle the material’s hardness, abrasiveness, or size requirements. With customized jaw plates, businesses can achieve better efficiency, longer service life, and reduce maintenance costs.

As jaw plates undergo constant wear and tear during crushing, monitoring their condition is essential for determining when they need replacement. One key sign is reduced efficiency. If the crusher isn’t processing material as effectively as before, the jaw plates may be too worn to apply the necessary pressure. Visible cracks or damage are another indication that the plates need replacing. Cracks can weaken the jaw plates, affecting the crushing process and potentially causing failure. Excessive wear is also a clear sign that the plates need to be replaced, especially if their surfaces become uneven or too smooth to grip materials effectively.

Regular inspections are critical for detecting early signs of wear, cracks, or damage. Inspections should be performed routinely, especially after extended use, to avoid costly breakdowns. Additionally, lubrication is essential to reduce friction between the jaw plates and extend their lifespan. Proper lubrication ensures smooth operation and helps prevent premature wear. Finally, timely replacement of worn-out jaw plates is necessary to avoid inefficient crushing and prevent further damage to the crusher. Replacing jaw plates promptly when they show signs of significant wear ensures that the crusher continues to function at peak efficiency, avoiding unnecessary downtime.

Jaw plates are crucial for efficient crushing operations, and selecting the right material, type, and design can significantly affect crusher performance. Ma'Anshan ONA Intelligent Equipment Co., Ltd. offers premium jaw crusher parts, including fixed jaw plates, designed for durability, wear resistance, and long-lasting performance.

For industries like mining, quarrying, and construction, investing in high-quality jaw plates from ONA helps maximize uptime, reduce costs, and improve efficiency.

Regular inspection, lubrication, and timely replacement of jaw plates are essential to ensuring consistent performance and preventing unnecessary downtime.

A: A jaw plate in a jaw crusher is used to crush and compress materials by applying pressure as they are fed between the movable and fixed plates, breaking them down into smaller pieces for further processing.

A: The crusher jaw plate works by pressing material against the opposite plate, where the force breaks the material into smaller chunks. The plates are designed to endure the wear and tear caused by crushing hard materials.

A: Jaw plates are crucial for crushers because they enable the crushing process by providing a durable surface for compressing and breaking down tough materials like ores, granite, and limestone. Their quality directly impacts crusher performance.

A: When choosing a jaw plate for a crusher, consider the type of material you are crushing and the jaw plate's material. For tougher materials, opt for heavy-duty plates made from high-manganese steel for better wear resistance.

A: There are standard jaw plates for general use, heavy-duty jaw plates for tougher materials, and customized jaw plates for specific crushing needs. Each type offers different levels of wear resistance and durability.