- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2026-01-29 Origin: Site

Have you ever wondered what makes jaw plates so durable in crushers? These crucial components are built to withstand extreme forces while breaking down tough materials. The choice of material greatly impacts their efficiency and longevity.

In this article, we’ll dive into the various materials used in jaw plates, examining their pros and cons. You'll gain insights into how each material affects crusher performance and how to make the best choice for your needs.

A jaw plate is a crucial part of the jaw crusher that works by applying pressure to break down materials. Typically, jaw crushers consist of two plates: a fixed jaw plate and a movable jaw plate, both of which work together to crush the raw materials. The fixed jaw plate remains stationary, while the movable jaw plate moves back and forth, creating a crushing action that forces materials between the two plates, breaking them apart.

The materials crushed by jaw crushers include ores, rocks, and aggregates, which need to be reduced in size for various industrial applications. The efficiency of a jaw crusher largely depends on the design and material of the jaw plates. Materials such as high manganese steel are preferred for their excellent wear resistance, ensuring long-lasting performance.

The jaw plate for crushers is arguably the most critical component in the entire crushing process. Its role is to exert pressure on the materials passing through the crusher, ensuring they are crushed to the required size. The quality of jaw plates directly affects the crusher's performance, wear rate, and the overall efficiency of the crushing operation. ONA’s fixed jaw plates, for example, are designed to provide high resistance to wear, corrosion, and deformation, significantly reducing downtime and maintenance costs.

High manganese steel is the most widely used material in jaw plates due to its superior toughness, hardness, and resistance to wear. This steel typically contains 12% to 14% manganese, which significantly improves its hardness and durability. During the crushing process, the surface of the high manganese steel hardens further due to work-hardening properties, increasing its wear resistance over time.

● Advantages of High Manganese Steel:Work-Hardening: As the jaw plates are used, the impact forces cause the material's surface to harden, improving its resistance to wear.

○ Toughness: High manganese steel is incredibly tough, making it well-suited for crushing tough materials such as granite and iron ore.

○ Cost-Effectiveness: Although high manganese steel may have a higher upfront cost, its longevity and reduced maintenance needs make it a cost-effective choice in the long run.

○ Examples in Use: ONA’s fixed jaw plates are made from high manganese steel, such as MN13, MN18, and MN22, which ensures durability in high-impact environments like mining and quarrying.

Alloy steel is another material often used for jaw plates. This steel is made by combining carbon steel with various alloying elements, such as chromium, molybdenum, and nickel. These alloying elements improve the material's hardness, toughness, and resistance to wear and fatigue. Alloy steel jaw plates are known for their strength and ability to withstand the stresses imposed during the crushing process.

Benefits of Alloy Steel:Enhanced Durability: Alloy steel provides better durability compared to carbon steel, making it suitable for high-load crushing applications.

Resistance to Fatigue: Alloy steel offers excellent fatigue resistance, ensuring the jaw plates can handle repetitive stress without cracking.

Tailored Composition: Depending on the specific alloying elements, alloy steel can be customized to meet specific operational needs, such as improved abrasion resistance for crushers working with highly abrasive materials.

Examples in Use: ONA’s alloy steel jaw plates are particularly effective in applications requiring high resistance to impact and wear.

Cast steel is a versatile material used in the manufacturing of jaw plates. It is particularly advantageous for large or custom-sized jaw plates due to its ease of manufacturing. Cast steel can be molded into complex shapes, making it suitable for large-scale production or specialized crusher models.

● Pros and Cons of Cast Steel:Pros: Cost-effective, ideal for large-scale production, and easy to mold into various shapes.

○ Cons: While cast steel is durable, it may not offer the same level of wear resistance or toughness as high manganese steel, particularly in high-impact applications.

○ Examples in Use: ONA’s cast steel jaw plates are commonly used for standard applications where cost-efficiency is prioritized over extreme wear resistance.

In addition to the primary materials, carbon steel and chromium steel are sometimes used in jaw plates for specialized applications. These materials offer unique benefits, such as enhanced heat resistance or the ability to withstand corrosion in certain environments.

● Carbon Steel:Carbon steel is commonly used in less abrasive environments where cost-efficiency is a priority. It provides adequate strength and hardness but lacks the high wear resistance of alloys like high manganese steel. This makes carbon steel an attractive, budget-friendly option for businesses needing jaw plates that perform well in softer crushing applications. However, it may wear out faster in high-impact environments, which makes it less ideal for highly abrasive materials. Carbon steel jaw plates are best suited for industries with lower crushing demands, offering a cost-effective solution without compromising basic performance.

● Chromium Steel: Chromium steel is known for its high resistance to corrosion and performs excellently in high-temperature environments. The addition of chromium improves its ability to withstand oxidation and corrosion, making it ideal for harsh applications where exposure to chemicals or moisture is common. Chromium steel jaw plates are highly durable in extreme conditions, offering extended lifespan and consistent performance in environments like chemical processing or high-temperature mining. However, they tend to be more expensive and may not provide the same toughness as materials like high manganese steel for abrasive applications.

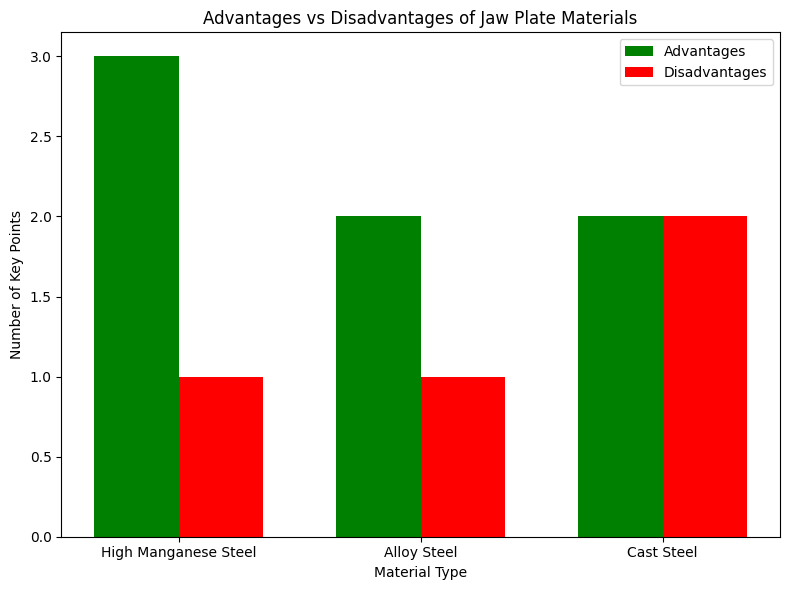

To provide a clearer comparison, here’s a chart highlighting the advantages and disadvantages of the three main jaw plate materials:

One of the main reasons for choosing high manganese steel for jaw plates is its toughness and hardness. This material can withstand the extreme forces generated during the crushing process without cracking or breaking. The work-hardening properties of high manganese steel allow the material to become even harder with continued use, ensuring that jaw plates maintain their crushing efficiency over time.

High manganese steel is highly resistant to wear and abrasion, especially in tough crushing environments. This is critical in industries like mining, where jaw plates are subjected to constant wear and tear from materials like rocks and ores. ONA’s high-quality jaw plates are designed to last longer, reducing the frequency of replacements and minimizing downtime.

As jaw plates made from high manganese steel are used, they undergo work-hardening, meaning the surface becomes harder and more resistant to wear. This self-hardened layer increases the longevity of the jaw plates, making them highly cost-effective in the long term.

Alloy steel is renowned for its exceptional strength and durability, making it an ideal material for jaw plates used in high-stress crushing environments. The addition of various alloying elements, such as chromium, nickel, and molybdenum, enhances the steel's ability to withstand extreme conditions. These elements not only increase the hardness of the steel but also improve its resistance to heat and corrosion. As a result, alloy steel jaw plates are able to handle immense pressure and continue to perform effectively without compromising their structural integrity. This makes them suitable for jaw crushers that process large volumes of hard and abrasive materials, such as ores and rocks, in industries like mining and quarrying.

Alloy steel jaw plates are also able to endure high-impact forces without cracking or deforming, which is essential in crushers that operate at high speeds. The strength of alloy steel helps prevent premature failure, which reduces maintenance costs and downtime, ultimately improving the operational efficiency of the crusher.

One of the standout features of jaw plates made from alloy steel is their remarkable resistance to both impact and abrasive wear. Crushing tough materials generates significant wear, and jaw plates need to be durable enough to resist damage from abrasive forces. Alloy steel jaw plates are engineered to withstand these conditions, maintaining their functionality and ensuring a longer service life.

ONA’s alloy steel jaw plates, for example, are designed with improved wear resistance and fatigue strength, ensuring that they can perform reliably even in demanding applications. These plates maintain their shape and effectiveness, minimizing the need for frequent replacements and reducing overall operating costs. The combination of alloying elements such as chromium and nickel enhances the steel’s ability to resist corrosion and high-temperature wear, which is particularly beneficial when dealing with hard and abrasive materials. This makes alloy steel jaw plates an excellent choice for crushers exposed to challenging environments and heavy workloads.

Cast steel is a material widely used in the manufacturing of jaw plates due to its ease of molding into complex shapes. This makes it a cost-effective option for large-scale production. Additionally, cast steel jaw plates are known for their ability to withstand moderate wear and stress while providing decent durability.

In applications that do not involve highly abrasive materials, cast steel may be the best material choice. It offers a balance of strength, cost-effectiveness, and performance, making it ideal for industries such as construction or aggregate production, where jaw plates are exposed to less demanding conditions.

Choosing the correct material for jaw plates depends on the crushing needs of the operation. For high-impact applications, such as mining and quarrying, high manganese steel is preferred for its toughness and resistance to wear. In contrast, for applications requiring more strength and less focus on wear resistance, alloy steel or cast steel may be better suited.

When selecting jaw plates, it is essential to balance cost and performance. High manganese steel, although more expensive initially, offers extended service life, reducing the need for frequent replacements. Conversely, cast steel is more affordable but may require more frequent replacements in high-wear environments.

Material Type | Advantages | Disadvantages |

High Manganese Steel | Toughness, wear resistance, work-hardening properties | Higher upfront cost |

Alloy Steel | High strength, resistance to fatigue, durability | May not offer the same wear resistance as manganese steel |

Cast Steel | Cost-effective, easy to mold into complex shapes | Prone to cracking under high-impact stress |

Selecting the right jaw plate material is crucial for optimizing the efficiency and longevity of jaw crushers. Whether you choose crusher jaw plates made of high manganese steel, alloy steel, or cast steel, each material offers distinct advantages depending on the specific crushing needs. ONA’s premium fixed jaw plates, made from high manganese steel and alloy steel, offer exceptional wear resistance, strength, and long service life, ensuring that your crushing operations remain efficient and cost-effective. Understanding the materials used in jaw plates will help you make an informed choice that best suits your specific requirements.

A: A jaw plate is typically made of high manganese steel, alloy steel, or cast steel. High manganese steel is particularly favored due to its wear-resistant properties and ability to work-harden during crushing operations.

A: High manganese steel is chosen for jaw plates because of its toughness and ability to harden under impact, providing superior wear resistance in high-stress crushing environments.

A: Jaw plates made from high manganese steel can last significantly longer compared to other materials due to their work-hardening properties, with service life extended by 20-30% in demanding applications.

A: Yes, jaw plates for crushers can be customized in terms of size, material, and tooth design to suit specific crushing needs, ensuring optimal performance for various applications.

A: Alloy steel offers enhanced strength, durability, and resistance to fatigue, making it suitable for heavy-duty jaw plates that need to withstand high-impact forces and abrasive materials.