- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-07-18 Origin: Site

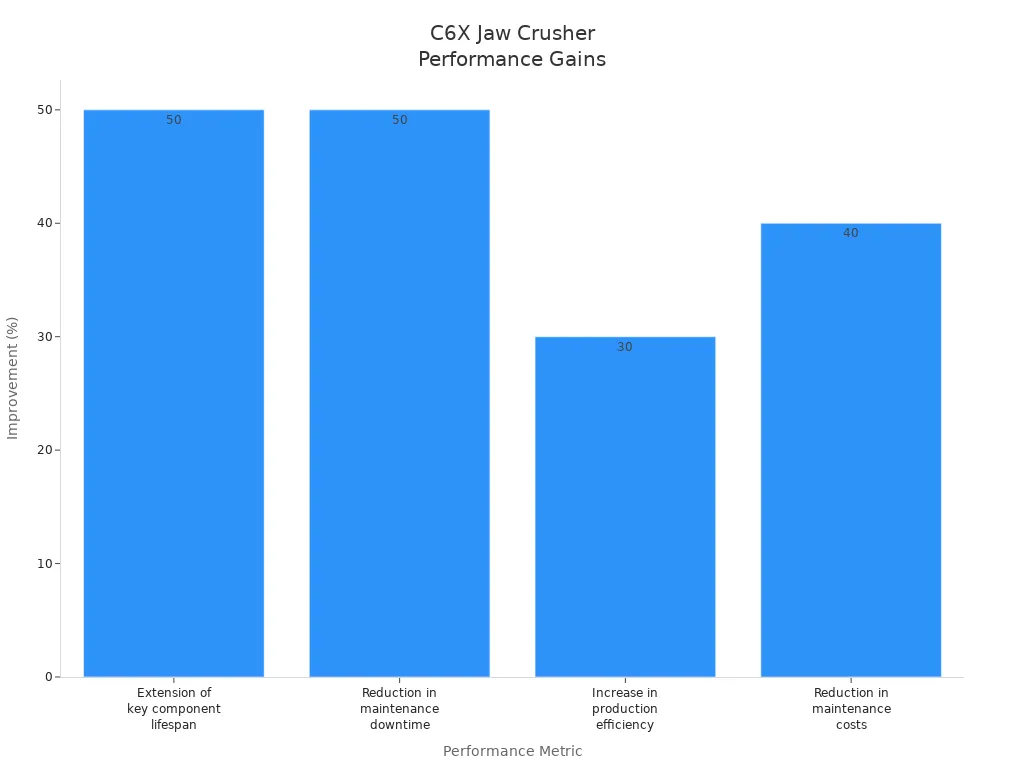

You want your jaw crusher to work well and not break down. Many people get upset when plates wear out or crack early. This can happen from bad lubrication, too much stress, or rough materials. Using good jaw crusher parts, like ONA’s fixed jaw plate, helps your machine last longer and work better. Strong plates mean less time fixing things and more money saved. Studies show that better plates can make parts last 50% longer and lower repair costs by 40%.

| Metric | Improvement with Upgraded Jaw Crusher Plates |

|---|---|

| Extension of part life | Up to 50% longer |

| Less downtime | 50% reduction |

| Higher efficiency | 30% increase |

| Lower maintenance costs | 40% decrease |

Picking the right plates and taking care of your jaw crusher keeps your machine safe and your business strong.

Use good jaw crusher parts and take care of them. This helps your machine last longer and work better.

Lubricate, clean, and check your machine often. This stops breakdowns and lowers repair costs a lot.

Put your jaw crusher on a strong, steady base. Check if it is lined up right often to stop uneven wear and damage.

Watch the size and type of material you feed into the crusher. This stops blockages and keeps parts from wearing out unevenly.

Teach workers and follow a good maintenance plan. This helps you find problems early and keeps your jaw crusher working well.

You help your jaw crusher last longer by using the right lubrication. Good lubrication lets plates and moving parts work well. Here are some easy steps to help your parts last longer and stop breakdowns:

Clean the lubrication filters and breather filters every 1,000 hours or as the maker says.

Check and clean the return oil screen every day so dirt does not build up.

Watch oil temperature and pressure each day to find problems early.

Use good grease or synthetic oils for better results, especially when it is tough.

Lubricate moving parts like the eccentric shaft and bearings every day.

Add offline filtration systems to make oil last longer and help with care.

ONA’s fixed jaw plate is made from high manganese steel. It works better when you do regular maintenance and use the right lubrication. This helps you get the most use from your wear parts.

Checking and cleaning your jaw crusher parts every day is very important. You should:

Look for wear or damage on plates and other wear parts.

Clean dust and dirt from moving parts to stop extra wear.

Change manganese liners when you see a 10% drop in how much you produce.

Check oil levels and filters every day, and clean or change them if needed.

Doing these things helps you take care of your machine and stops sudden problems.

A good maintenance plan helps your jaw crusher last longer. Follow this routine:

Before you use it: Clean off dirt, check fluids, and look for leaks.

Every week: Check jaw dies, cheek plates, bolts, and discharge settings.

Every month: Look at belts, guards, hydraulic systems, and change oils.

Write down your maintenance work in a log. This helps you keep track of jaw die care and find problems early.

Some people make mistakes that make plates and jaw crusher parts wear out faster. Be careful about these things:

Loose bolts from shaking—tighten them often.

Worn plates—change them before they break.

Bearing problems from bad lubrication or parts not lined up right.

Wrong feed size can make plates wear unevenly.

Skipping regular maintenance or care.

Not flipping or swapping plates to help them last longer.

Using strong, wear-resistant plates like ONA’s fixed jaw plate and having a good maintenance plan helps you avoid these problems and makes your parts last longer.

A strong base keeps your jaw crusher safe and steady. First, make a concrete base that can hold the machine’s weight. Clear the area and dig a hole that is deep enough. The hole should be about 1.5 to 2 times as tall as your crusher. Pour the concrete and let it dry all the way before you keep going.

Use a crane or hoist to lift the jaw crusher onto the base.

Line up the machine with the feed and discharge belts using a level.

Bolt the crusher down with anchor bolts and tighten them well.

Check again to make sure everything is lined up right.

Tip: Check the anchor bolts often for looseness or damage. Tighten or change them if needed so the machine does not move when working.

A steady base cuts down on shaking and helps jaw crusher parts last longer.

Good alignment keeps your jaw crusher from wearing out too soon. Make sure the eccentric shaft fits just right in the bearings. Use a level to check that the sliding bearings are at the right angle. Put special pads between the frame and the base to keep things steady.

If things are not lined up, parts can wear out unevenly and bearings can break.

Good lubrication starts with bearings put in the right way and filled with grease.

Heat the bearings evenly and push them in gently so they do not get damaged.

Scrape off high spots on plain bearings so at least 80% of the area touches. This helps the shaft last longer.

Careful alignment checks help your jaw crusher work well and make the parts last longer.

Too much shaking can hurt your jaw crusher and make parts wear out faster. You can stop this by making sure the base is strong. If you see shaking, add more support with rubber strips or blocks. Always check where the flywheel is and tighten bolts if needed.

Look at the main base to make sure it is steady.

Put rubber strips or pads under the machine to soak up shocks.

Keep the flywheel in the right spot to stop extra stress.

Note: Less shaking means your jaw crusher parts wear out slower and break less often.

Doing these things helps your jaw crusher work well for a long time.

Feed size plays a big role in how long your jaw crusher parts last. If you feed material that is too large, you can cause blockages and make the plates wear out faster. You should keep the feed size below 80% of the crusher’s feed opening. Here are some steps to help you manage feed size:

Remove oversized rocks before they reach the crusher.

Pre-screen fines to improve the mix of particles.

Give your crusher a well-graded feed to help the plates last longer.

Avoid sticky or lightweight materials that can cause clogs.

Limit steel or metal in the feed to prevent damage.

These steps help you avoid blockages and uneven wear. They also make your crusher work better and last longer.

The type of material you feed into your jaw crusher changes how fast the parts wear out. Hard and abrasive rocks like granite or quartz need plates made from high manganese steel. Softer materials, such as asphalt or concrete, work well with medium manganese steel plates. You should also think about the size and shape of the feed. Avoid oversized pieces and use dust control to keep abrasive fines low. For feeds with lots of fines, choose jaw plates with wide teeth so the fines can pass through easily. Flip or rotate your jaw plates often to make sure they wear evenly.

Good flow management keeps your jaw crusher running smoothly. You want to match the feed speed and size to your crusher’s capacity. Use vibrating feeders to control how much material goes in. Check your crusher often for signs of uneven wear. Keep the feed rate steady and avoid overloading. Watch the crusher’s speed and chamber settings. Adjust these settings as needed to get the best performance. These factors affect the wear of your jaw crusher parts and help you get the most out of your equipment.

You can spot early problems in your jaw crusher by listening for strange noises and checking for extra shaking. Vibration and noise often show up before a part fails. When you use vibration monitoring, you track changes in how the machine moves. If you notice new or louder sounds, you might have loose bolts, misaligned parts, or an unbalanced shaft. These issues can lead to bearing damage or cracks in the frame. Experts recommend checking for 1xRPM and 2xRPM vibration patterns. These patterns help you find imbalances or loose parts. You should also make sure the foundation is solid and the pulley is balanced. Regular checks help you fix small problems before they become big ones.

You should watch the temperature of your jaw crusher parts, especially the bearings and hydraulic oil. A sudden rise in temperature often means something is wrong. If the hydraulic oil goes above 80°C, you may have too much wear or a problem with lubrication. Worn bearings can also get hot, make more noise, and shake more than usual. Check for these signs every day. If you see or feel a hot spot, stop the machine and inspect it. Keeping parts cool and well-lubricated helps them last longer.

You can prevent big failures by catching problems early. Start with daily visual checks. Look for cracks, chips, or worn spots on plates and liners. Listen for odd sounds and watch for extra shaking during operation. Keep a log of your inspections and repairs. This helps you spot patterns and plan maintenance before something breaks. Make sure you install and align parts correctly. Train your team to notice changes in sound or performance. Use screens and magnets to keep out metal or oversized rocks. Clean dust seals and check lubrication often. These steps can cut down on early failures by up to 30% and help your jaw crusher parts last much longer.

You help keep jaw crushers working well. Operators with good skills stop breakdowns and save money. Training helps when older workers leave. You learn to change crusher settings and use digital tools. Training shows you how to spot problems early, like new noises or shaking. You get to practice on real machines with help from experts. Workshops teach you the best ways to do your job. Learning all the time helps you know new tricks and tools. When you know how your work affects the machine, you help your team stay safe and avoid problems.

Training teaches you:

How to feed the crusher the right way

How to change settings to stop extra wear

How to use vibration checks to find problems early

How to understand the whole process for better choices

A good care plan stops big problems before they start. You should look at important parts often to find damage early. Regular care means checking oil, air filters, and grease. Clean and fill grease spots to keep things moving. Write down all care jobs so you do not forget anything. When the machine is off, you can practice fixing things and learn new skills. Your care plan should show you how to fix small problems before they get worse. Preventative care also means using the machine the safe way. When you focus on care, jaw crusher parts last longer and your work goes better.

Check parts for damage or wear

Grease moving parts like bearings and gears

Watch for shaking and heat

Keep good notes on care jobs

Practice fixing things when the machine is off

Safety training keeps you and the machine safe from harm. Always check that guards and emergency stops work before you start. Follow the maker’s rules and never clear jams while it runs. Use lockout/tagout steps to stop accidents during care. Feed the crusher with the right size rocks to stop jams. Wear safety gear and stay away from moving parts. Use remote tools to clear jams if you can. Keep the area clean and handle materials safely to stop dangers. Emergency stops and clear paths help you get out fast if needed. A good care plan has regular safety checks and training for everyone.

You can help your jaw crusher work better by getting new plates and parts. When you pick plates made from strong materials, your machine lasts longer. These plates do not break or wear out quickly. Many people see their machines last longer with high manganese steel or special alloys. These plates have a hard outside and a tough inside to stop cracks. Custom plates fit your crusher well and mean less time fixing things. You also save money because you do not need to change plates as much. Upgrading plates helps your crusher work longer and better.

The kind of material in jaw plates matters for how long they last. You should use plates made from high manganese steel like Mn13, Mn18, or Mn22. These plates get harder as you use them, so they last longer. Some plates have bi-metal composites or tungsten carbide inserts for extra strength. These materials help stop wear and damage. Good casting and careful checks make sure the plates are strong and fit right. In mines, these plates last over 20% longer than regular ones. You get more use from your plates and spend less time fixing your crusher.

Common advanced materials for jaw crusher plates:

High manganese steel (Mn13, Mn18, Mn22)

Bi-metal composites

Tungsten carbide inserts

You can make your jaw crusher last longer by adding new plates and parts to old machines. Retrofitting means putting new plates or systems on your old crusher. This helps your equipment last longer without buying a new one. Many companies see their plates last up to 300% longer after retrofitting. You also have less downtime and save money. Retrofitting can be hard because you need to check your machine and plan the changes. If you work with experts, you get plates that fit well and last longer. Retrofitting gives your crusher new life and helps you work safely and well.

You need to know when to replace jaw crusher plates to get the best service life from your machine. If you wait too long, worn plates can lower your crusher’s performance and even damage other parts. Check your plates often for signs of deep grooves, cracks, or a sharp drop in output. Replace plates when you see about 70% wear or when the lower area of the fixed plate gets thin. Changing plates at the right time keeps your crusher working well and helps you avoid costly downtime. Using high-quality plates, like ONA’s fixed jaw plate, gives you a longer service life and more reliable performance.

You can make your plates last longer by rotating them at the right intervals. Rotating jaw plates helps you get even wear across the whole surface. This means you use more of the plate before needing a replacement. Here’s how rotating plates helps:

You spread wear evenly, so you use more of the plate’s material.

You keep the best crushing angle, which helps the crusher work better.

You avoid weak spots that can lead to cracks or breaks.

You delay replacement, which saves money and extends the life of your plates.

For two-piece plates, move the worn plate from the bottom to the top to get more use.

Tip: Rotate fixed plates after about 30% wear in the lower area, then again when the new lower area wears out. This practice helps you get the most service life from each set of plates.

Better plate design can make a big difference in how long your jaw crusher parts last. Symmetrical plate designs let you rotate or flip plates, which helps you get even wear and longer service life. Plates made from high manganese steel, like those from ONA, get tougher as you use them. Special heat treatment makes the plates even stronger and more resistant to wear. These improvements can boost the life of your plates by up to 200%. You also get a better fit, which means less downtime and easier replacement. Some crushers use hydraulic wedge settings and advanced monitoring systems to keep everything running smoothly. When you choose plates with these features, you get the best service life and performance for your jaw crusher.

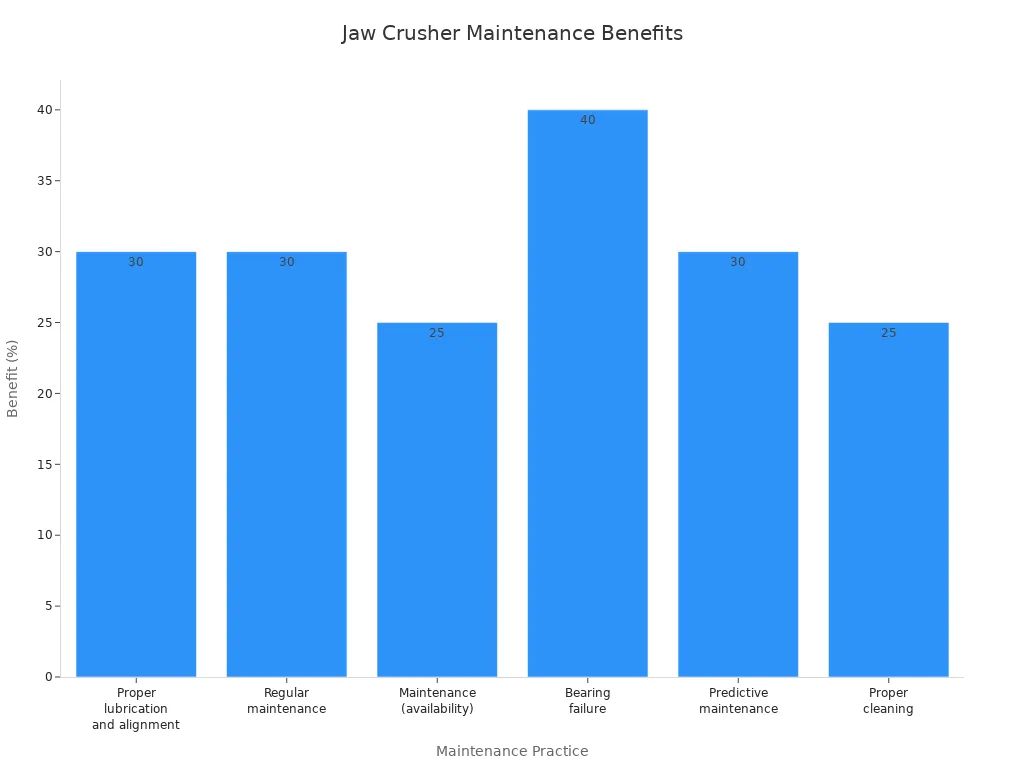

You can make jaw crusher parts last longer by taking care of them. If you keep up with maintenance, install parts the right way, and use good parts, your jaw crusher will work better and not break as fast. One mining company did more maintenance and changed parts on time. They made 15% more and spent 20% less money. The table below shows other good things that happen when you do maintenance:

| Maintenance Practice / Factor | Benefit / Statistic |

|---|---|

| Proper lubrication and alignment | Extends jaw plate life by up to 30% |

| Regular maintenance | Prolongs machinery life by up to 30% |

| Maintenance | Improves equipment availability by 20-30% |

Look at how you take care of your jaw crusher now. Watch the parts and change them when needed. These steps help your jaw crusher work its best.

You should check your jaw crusher parts every day. Look for signs of wear, cracks, or loose bolts. Daily checks help you catch problems early and keep your machine running well.

You can reduce wear by using high-quality plates, like ONA’s fixed jaw plate. Keep the feed size correct and rotate plates when needed. Regular maintenance also helps your plates last longer.

Feed size affects how fast your plates wear out. Large or uneven rocks can cause damage. Keep the feed size below 80% of the crusher’s opening for best results.

Replace a jaw plate when you see deep grooves, cracks, or a big drop in output. Do not wait until the plate breaks. Timely replacement keeps your crusher safe and efficient.

ONA’s fixed jaw plate fits most standard jaw crushers. You can also order custom sizes to match your machine. Always check the fit before you install a new plate.