- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Ever wonder why some crushers last longer than others? The answer often starts with the jaw plate. In this guide, you’ll discover what a jaw plate is, how it works, and how to choose the right one.

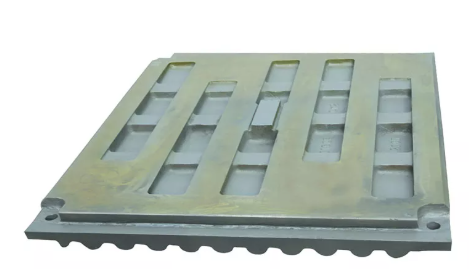

A jaw plate is the primary crushing surface installed inside a jaw crusher. It grips incoming material and applies compressive force to break rock, ore, or recycled debris into smaller sizes. During operation, the jaw plate is exposed to continuous impact, abrasion, and cyclic loading, making it one of the most stressed components in the entire crushing system. Because it directly influences material flow, particle reduction, and chamber efficiency, the jaw plate plays a decisive role in overall crusher performance. When properly selected, it helps maintain stable throughput, consistent product size, and predictable maintenance cycles. When poorly matched, it can lead to premature wear, increased power consumption, and unplanned downtime. For this reason, the jaw plate is widely regarded as the most important wear part in any jaw crusher.

Simply put, a jaw plate is a replaceable wear liner mounted inside a jaw crusher. It is not the crusher itself, nor is it part of the drive or transmission system. Instead, it is designed as a sacrificial component that absorbs wear so that critical structural parts of the crusher remain protected. Jaw plates are manufactured from high-strength materials such as high manganese steel or alloy steel, allowing them to withstand heavy impact while resisting surface abrasion. Since they are consumable parts, jaw plates are engineered for periodic replacement as part of routine maintenance planning. This design philosophy allows operators to restore crushing performance quickly without dismantling the entire machine.

Every jaw crusher operates using two jaw plates arranged opposite each other inside the crushing chamber. One is a fixed jaw plate, which is securely bolted to the stationary frame of the crusher. The other is a swing jaw plate, mounted on the moving jaw, also known as the pitman. The gap between these two plates forms the crushing chamber. As material enters from the top, it is progressively compressed as it moves downward through this space. The geometry of the jaw plates, together with their positioning, determines how material flows through the crusher and how efficiently size reduction occurs. Proper alignment of both plates is essential for even wear distribution and stable operation.

The fixed jaw plate serves as a stable reaction surface during crushing. It remains stationary and absorbs much of the compressive force generated by the moving jaw. In contrast, the swing jaw plate moves forward and backward in a reciprocating motion, applying pressure to the material and drawing it deeper into the chamber. Because the swing jaw plate actively contacts incoming feed, it often experiences higher impact loads, especially in the upper crushing zone. As a result, wear patterns between the two plates typically differ. The swing side may show more impact-related damage, while the fixed side may exhibit smoother abrasive wear. Understanding this difference helps operators plan rotations or replacements more effectively.

Crushing in a jaw crusher happens primarily through compression. Material enters the chamber from the top and becomes trapped between the fixed and swing jaw plates. As the swing jaw moves inward, pressure builds until the material fractures along natural weakness points. Once broken, smaller particles fall deeper into the chamber, where they may be compressed again before reaching the discharge opening. This repeated compression continues until particles are small enough to exit. Effective jaw plate design ensures sufficient grip during this process, preventing material from slipping upward and maintaining steady throughput. Poor grip can cause cycling, reduced capacity, and increased energy consumption.

Jaw crusher plates are available in flat, corrugated, and toothed profiles, each designed to suit specific crushing conditions. Flat jaw plates are typically used for softer or less abrasive materials, offering smoother wear and reduced risk of tooth breakage. Corrugated plates provide stronger grip and are widely used in general aggregate applications. Toothed or quarry profiles improve bite on blocky or slippery feed, helping draw large material downward more efficiently. Each profile influences not only grip strength but also material flow, power draw, and wear distribution across the plate surface. Aggressive tooth designs can improve productivity in challenging feed conditions, but they may also increase metal loss when processing highly abrasive rock. Selecting the right profile requires balancing crushing performance against wear life.

True jaw plate compatibility involves more than matching overall dimensions. Plates must also align precisely with chamber geometry, seat design, bolt patterns, and backing systems. Even small deviations in fit can cause movement during operation, leading to vibration, uneven wear, and potential damage to the crusher frame. A properly fitted jaw plate sits firmly against its mounting surface, distributes load evenly, and maintains consistent contact throughout the crushing cycle. Poor fit not only shortens jaw plate life but can also compromise the integrity of the crusher itself. For this reason, professional suppliers emphasize precision machining and OEM-level tolerances when producing jaw crusher plates.

The crushing process follows a cycle of entry, nip, fracture, and discharge. Most size reduction occurs in the mid-to-lower chamber where compressive forces peak.

Performance depends on more than plate strength alone. Feed size distribution, moisture, clay content, and Closed Side Setting (CSS) strongly influence wear and output. A tighter CSS increases reduction but accelerates wear, while a wider CSS improves capacity but lowers fines production.

Jaw plates also show distinct wear zones. The upper section handles impact from large feed, the middle section sees maximum crushing pressure, and the lower section experiences abrasion from fine particles. Off-center feeding shifts these zones and shortens plate life.

Comment: Centered feeding improves jaw plate life, product consistency, and overall crusher efficiency.

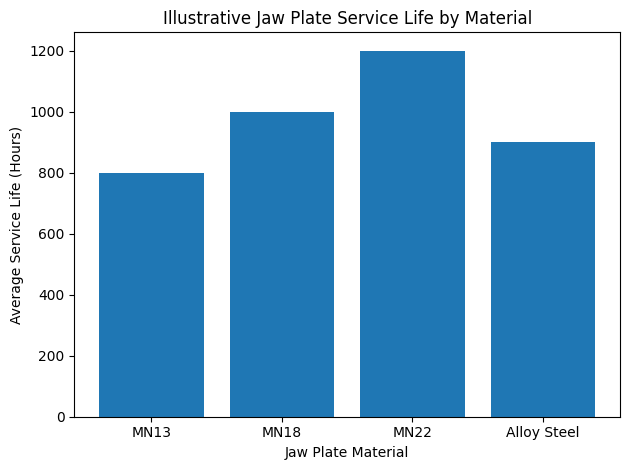

High manganese steel (MN13, MN18, MN22) remains the most common jaw plate material. It offers excellent toughness and work-hardening properties, making it ideal for high-impact applications such as crushing iron ore, limestone, copper ore, sandstone, and quartz.

Alloy steel jaw plates provide higher initial hardness and suit environments where abrasion dominates and impact remains moderate. Composite jaw plates use inserts or hybrid structures to extend service life by protecting high-wear zones.

A simple rule applies: prioritize toughness for impact-heavy conditions and wear resistance for abrasive conditions. Mixed environments benefit from balanced alloy designs.

Selection should start with understanding material hardness, abrasiveness, moisture level, and contamination risk. Profile choice depends on grip requirements. Wet or rounded feed often needs more aggressive bite, while soft limestone performs well with smoother surfaces.

Buyers should evaluate jaw crusher plates using cost-per-ton metrics rather than unit price alone. Longer service life, fewer stoppages, and stable throughput usually deliver better ROI.

Before ordering any crusher jaw plate or jaw plate for crusher, confirm the crusher model, CSS range, maximum feed size, and mounting design. Many customers search for “jaw crusher plates for sale,” but accurate RFQs require technical details such as chamber type and target service life.

ONA is a leading manufacturer of premium jaw crusher parts, specializing in fixed jaw plates for mining and quarry operations. ONA fixed jaw plates are produced using forging, precision machining, and surface treatment to ensure strength, accuracy, and durability.

Their products are available in MN13, MN18, and MN22 high manganese steel, offering excellent wear resistance, corrosion resistance, and deformation resistance. All plates are CE and ISO 9001:2008 certified and provide a perfect OEM fit.

Key advantages of ONA fixed jaw plates include:

● Service life 20–30% longer than standard parts

● High temperature resistance for harsh environments

● Custom tooth profiles and materials

● Smooth polished surfaces

● Secure iron pallet packaging

ONA fixed jaw plates are widely used in mining, quarrying, metallurgy, construction, chemical processing, and silicate industries. Each plate is carefully built to reduce replacement frequency and support continuous production.

With MOQ starting at 1, 30-day production time, and flexible payment options, ONA provides customized jaw crusher plates for sale to meet diverse customer needs.

Send your crusher model and material type to receive a tailored jaw plate solution from ONA.

Proper jaw plate maintenance is essential for maintaining crusher efficiency and avoiding costly downtime. Uneven wear most commonly results from off-center feeding, which concentrates crushing force on one side of the chamber. Localized tooth breakage, on the other hand, is usually caused by tramp metal, oversized feed, or sudden impact loads.

Jaw plates should be rotated whenever uneven wear becomes visible, provided sufficient thickness remains. Rotation helps balance wear across the surface and protects the seating area from premature damage. Full replacement is required once the mounting face weakens, cracks appear, or minimum thickness limits are reached.

Understanding wear patterns allows operators to correct problems early:

● Side-heavy wear: Typically caused by misaligned or uneven feeding.

● Upper-zone impact damage: Often linked to oversized feed or poor scalping.

● Smooth polishing in lower zones: Indicates high fines content or abrasive material.

● Tooth chipping or cracking: Usually caused by tramp metal or excessive shock loads.

● Accelerated center wear: May result from overly tight CSS settings.

Each pattern provides insight into operational issues that can be corrected upstream.

Several performance indicators often appear before visible jaw plate failure. Operators may notice rising power draw without any corresponding increase in throughput, along with reduced production even though feed supply remains stable. Increased vibration or abnormal operating noise can also signal developing wear issues. In many cases, product size becomes inconsistent or material begins to recirculate excessively inside the chamber. Another common warning sign is material slipping instead of drawing downward through the crusher. Ignoring these early symptoms can accelerate wear and eventually lead to secondary damage to critical components such as crusher frames, bearings, and toggle systems.

Rotation is appropriate when wear is uneven but structural integrity remains intact. Replacement becomes necessary when:

● Seating areas show deformation

● Cracks appear near bolt holes

● Plate thickness drops below safe operating limits

● Tooth profiles collapse and reduce grip

Always follow OEM minimum thickness guidelines to avoid unsafe operation.

Small operational improvements often deliver significant gains in jaw plate longevity:

● Maintain centered feeding to distribute wear evenly

● Use consistent feeder speed to avoid shock loading

● Control CSS to balance reduction and wear rate

● Install magnets or metal detectors to remove tramp steel

● Avoid surge feeding that overloads the chamber

● Pre-screen fines to reduce abrasive polishing

● Monitor wear weekly and document with photos

Establishing a basic inspection schedule helps identify problems early and supports predictive maintenance planning.

During routine inspections, operators should verify feed alignment, check jaw plate bolt tightness, visually inspect wear zones, and measure remaining plate thickness to ensure safe operation. It is also important to review power consumption trends and listen carefully for abnormal vibration or noise, as these can indicate developing mechanical issues. In addition, keeping detailed records of jaw plate service life, operating hours, and processed material type helps refine future plate selection and supports more accurate cost-per-ton performance analysis.

Comment: A structured wear log combined with centered feeding can extend jaw plate life by 15–30% (validation required).

A jaw plate is the replaceable crushing surface that determines grip, wear rate, and production output. The best results come from matching jaw plate profile and material to feed conditions and operating settings.

ONA premium fixed jaw plates from Ma'Anshan ONA Intelligent Equipment Co., Ltd. combine precise fit, advanced metallurgy, and extended service life to help operators achieve higher productivity and lower downtime. When jaw plates are treated as performance components rather than basic spares, crushing operations become more predictable, efficient, and profitable.

A: A jaw plate is a replaceable wear liner inside a crusher jaw plate that compresses material for size reduction.

A: It mounts on fixed and swing jaws, forming the chamber used by jaw crusher plates.

A: Off-center feeding, tight CSS, or tramp metal often cause uneven wear on jaw crusher plates.

A: Match material hardness, profile, and fit to your crusher jaw plate application.

A: Only if dimensions, seating, and metallurgy match your jaw plate requirements.